What Does The Appearance of Your Current Carbide Overlay Plate Tell You?

Are You Really Getting What You Paid For? The Hidden Flaws in “Premium” Carbide Overlay Plates

When you invest in a carbide overlay plate, you expect it to deliver—longer service life, reduced downtime, and top-tier performance. But here’s the truth: not all chromium carbide or complex carbide overlay plates are created equal. And if you’re not careful, you could be paying premium prices for subpar results.

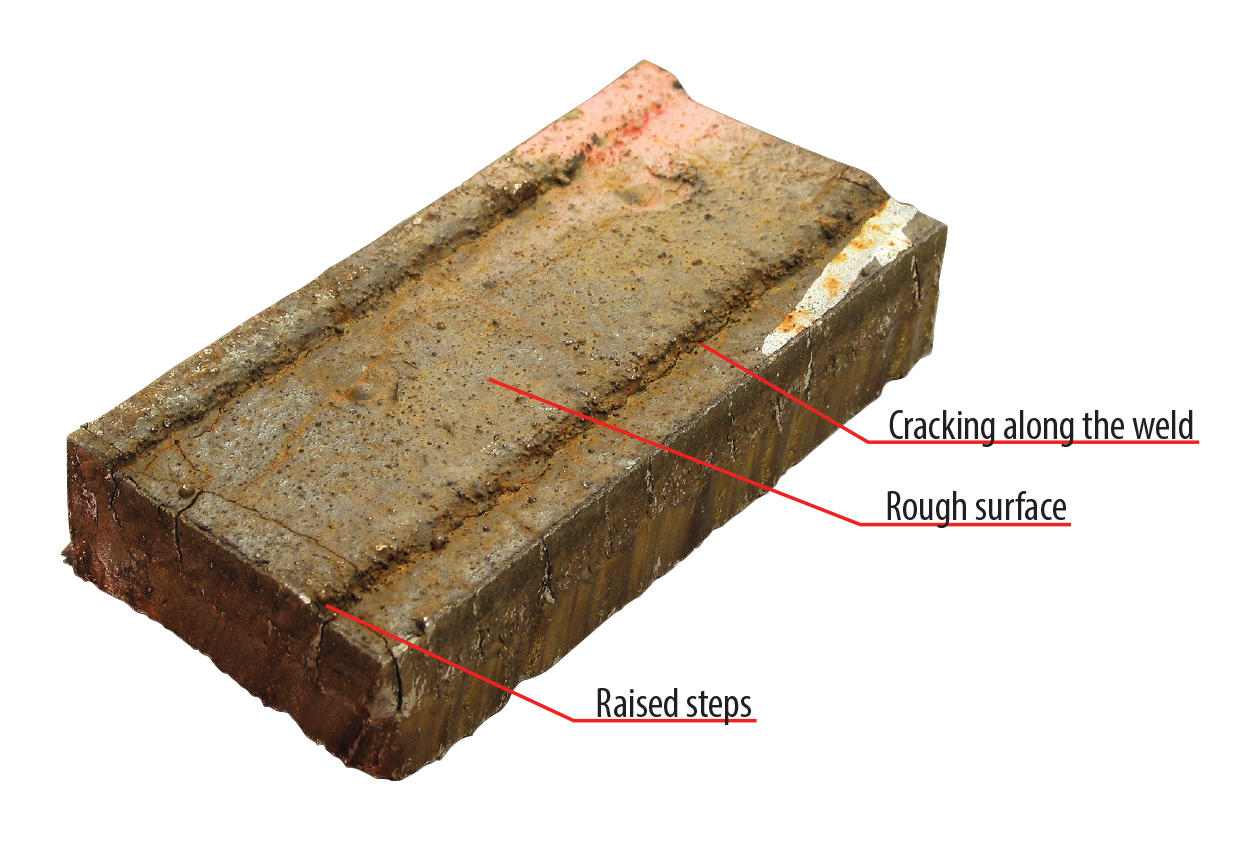

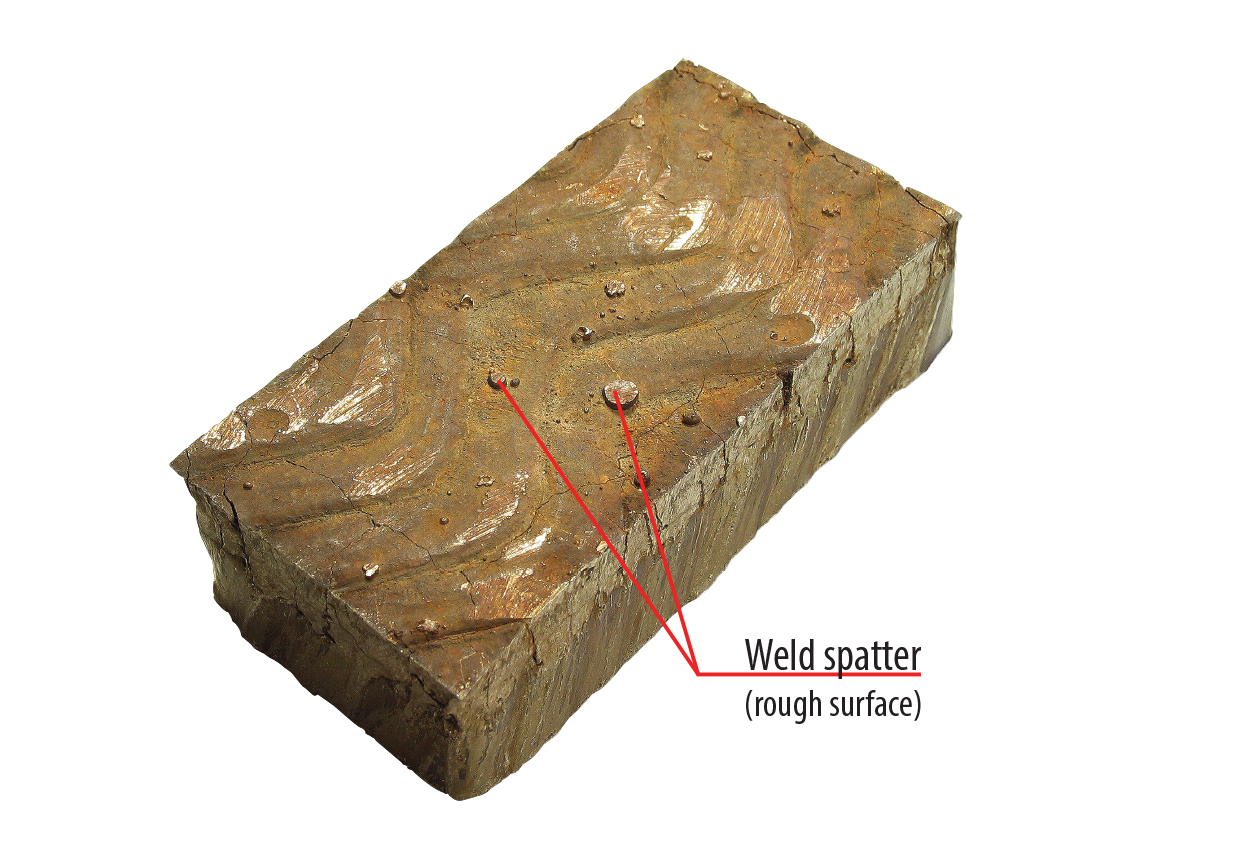

Surface Finish Matters More Than You Think

Take a close look at the surface of many carbide overlay plates on the market. You’ll often find a rough, uneven texture with a high coefficient of friction. Sure, it’s not a beauty contest—but that surface finish has real operational consequences.

In hoppers, chutes, and haul trucks, a rough surface can cause material hang-up, sticking, and carry-back. That means reduced material flow, less efficient throughput, and more wear on your equipment. Every ton that doesn’t move smoothly is money left on the table.

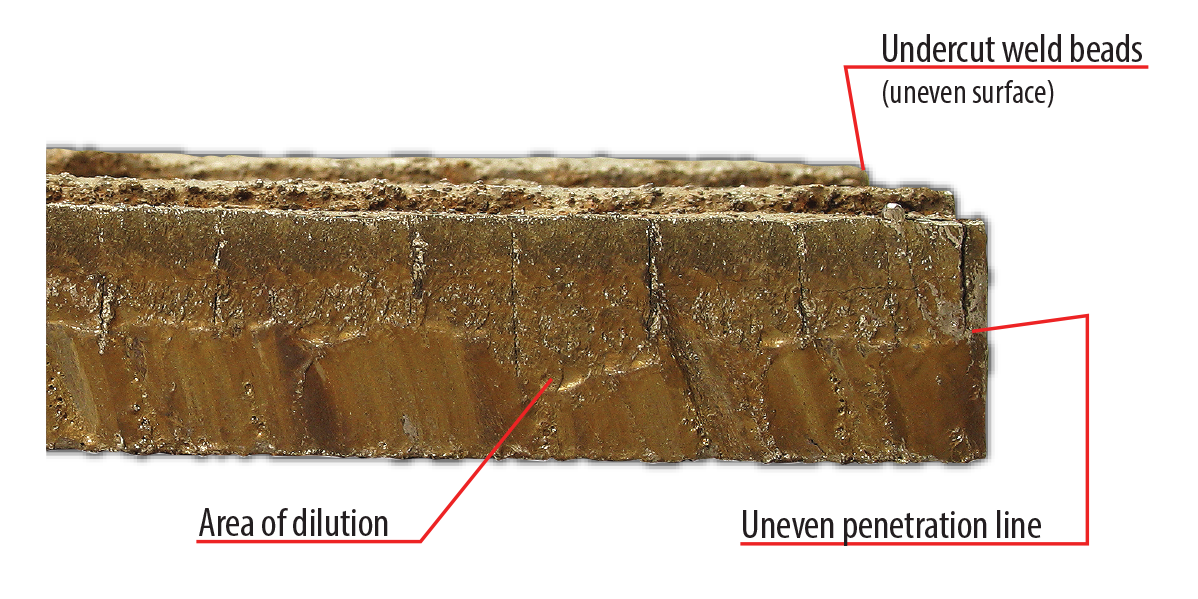

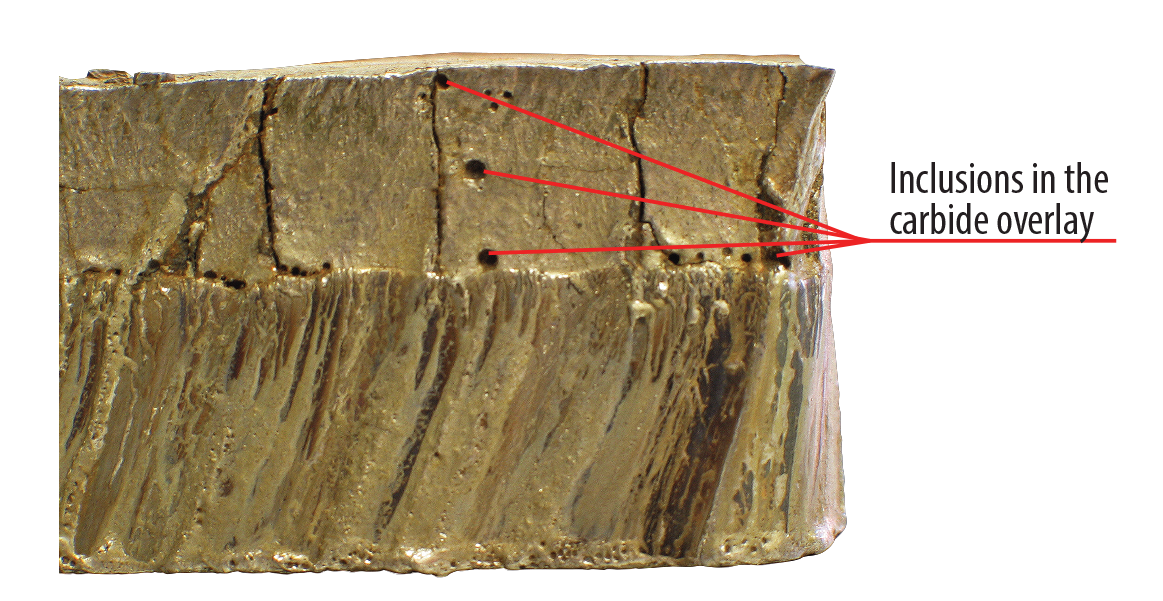

What’s Beneath the Surface Can Hurt You

Without rigorous quality control, small inclusions—tiny holes or voids—can form within the carbide overlay. These flaws weaken the material’s integrity and lead to spalling, chipping, or premature wear. That’s not something you want to discover halfway through a job.

Another critical issue? Poor penetration lines. If the bond between the overlay and the base plate isn’t consistent and deep enough, you’re in trouble. Low penetration can lead to delamination and spalling. On the flip side, areas where the overlay dips too low into the base material dilute the carbide microstructure. That dilution means fewer hard carbides where you need them most—and dramatically reduced wear resistance.

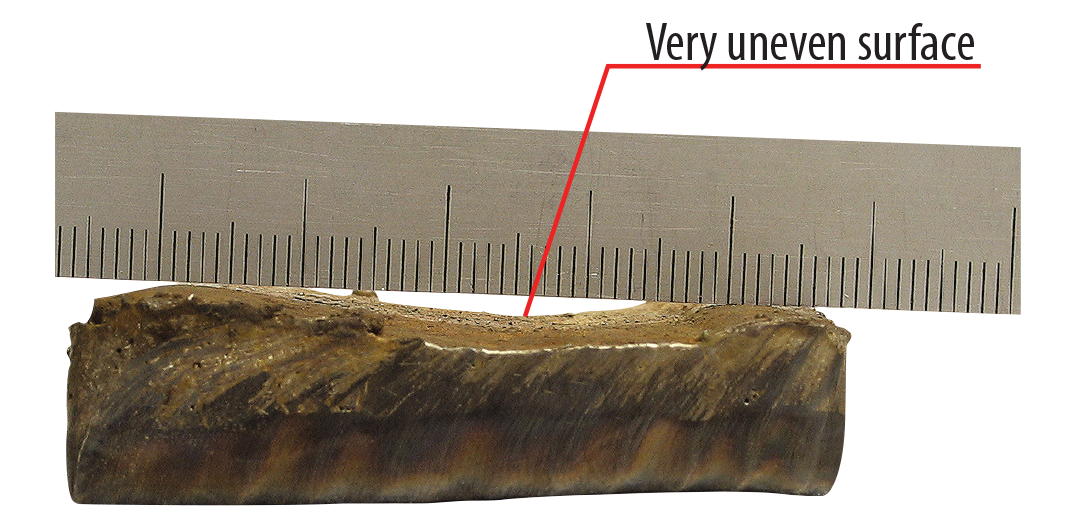

Flatness Is Fundamental

Don’t overlook flatness. A warped or uneven carbide overlay plate creates turbulence in material flow. This not only leads to faster wear but can also cause serious efficiency issues in your system. Uneven surfaces disrupt smooth, linear flow and create more points for materials to catch, build up, or degrade performance.

Demand More From Your Carbide Overlay Plate

At SAS Global Corporation, we believe you shouldn’t have to settle. You deserve carbide overlay plates that live up to their “premium” label. Our SureAlloy® Premium Carbide Overlay Plates are engineered for durability, consistency, and performance.

So if your current plate shows signs of rough surfaces, poor bonding, or uneven wear—it might be time to reconsider what “premium” really means.

Experience the difference with SureAlloy®—the true premium in carbide overlay plates.