STEEL INDUSTRY: SOLUTIONS FOR WEAR, PROCESS & EQUIPMENT

Comprehensive Wear Protection | Enhanced Process Efficiency | Superior Material Handling

SAS Global Corporation stands as a comprehensive provider for the steel industry's wear protection, material handling, and processing needs. Beyond fabrication, we develop and produce proprietary wear-resistant materials, ensuring solutions that are precisely tailored to your specific requirements. Each product is meticulously engineered to extend equipment service life and enhance operational performance.

Our offerings include:

- High-Performance Liner Systems

- Hardfacing Services

- Material Handling Components

- Processing Components

We cater to various segments within the steel industry, providing specialized solutions for:

- Electric Arc Furnaces (EAF)

- Direct Iron Reduction Plants

- Blast Furnaces

- Basic Oxygen Furnaces (BOF)

- Coke Plants

Our expertise also encompasses wear-resistant solutions for equipment such as:

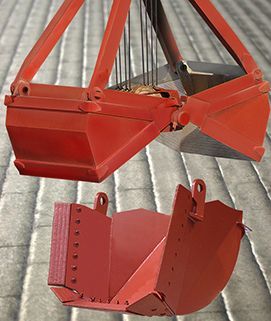

- Wheel Loader and Clamshell Buckets

- Chutes, Hoppers, and Liners

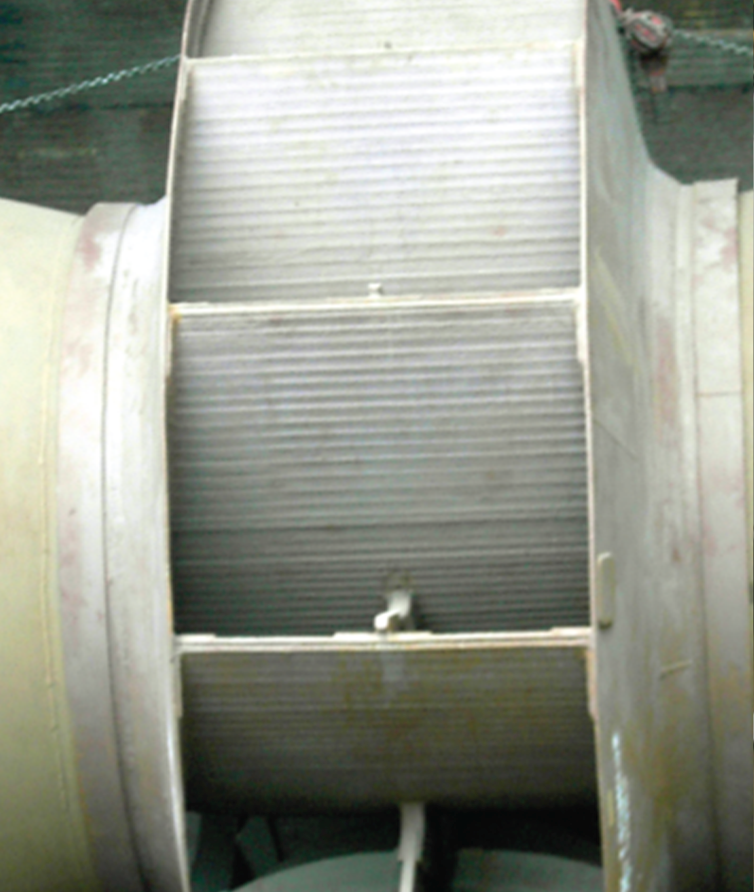

- Industrial Fans and Fan Housings

- Abrasion Resistant Pipe: Cladded and Fabricated

By integrating SAS Global's advanced materials and engineering, steel mills can achieve enhanced durability, reduced maintenance downtime, and optimized operational efficiency.

Explore a specific SAS Steel Industry Component or Service Below:

Mobile Mining Equipment Solutions

Electric Arc Furnace (EAF) Wear Resistant Solutions

Processing & Material Transfer Equipment

Direct Reduction Iron Wear Resistant Solutions

Mining On-Site Installation & Repair

Blast Furnace Wear Resistant Solutions

Underground Mining Solutions

Basic Oxygen Furnace (BOF) Wear Resistant Solutions