METAL RECYCLING INDUSTRY: SOLUTIONS FOR WEAR, PROCESS & EQUIPMENT

Engineered for Uptime | Built for Harsh Conditions | Proven to Reduce Maintenance Costs

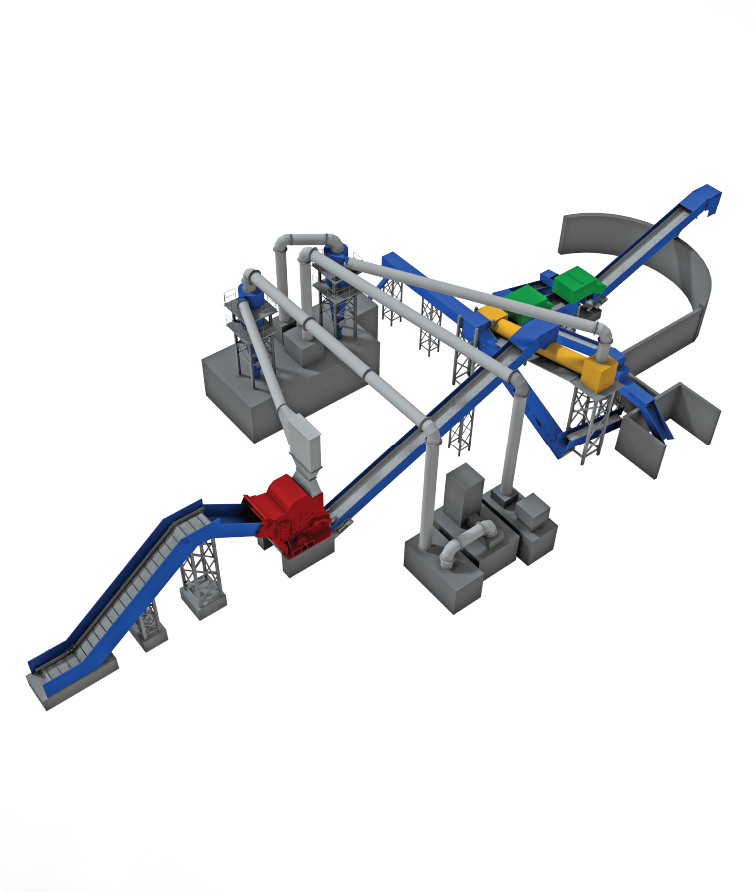

Metal recycling is tough on equipment—high impact, extreme abrasion, and continuous operation push components to their limits. That’s why SAS Global offers heavy-duty wear solutions engineered specifically for the demanding environments of auto shredders, shears, bailers, and material handling systems.

From shredder housings to fan systems, we deliver field-proven liners, components, and hardfacing solutions that reduce unplanned maintenance, extend uptime, and provide a measurable return on investment. Best of all, we develop and manufacture our own proprietary wear materials, including SureAlloy® and Vanguard®, giving you access to next-level durability that goes beyond off-the-shelf solutions.

Metal Recycling Equipment We Protect:

Mega / Auto Shredders

- Rotor assemblies, caps, grates, hammers, wear liners, feed rolls, and discharge chutes

- Fabricated from premium abrasion-resistant materials to survive high-velocity impacts and harsh environments

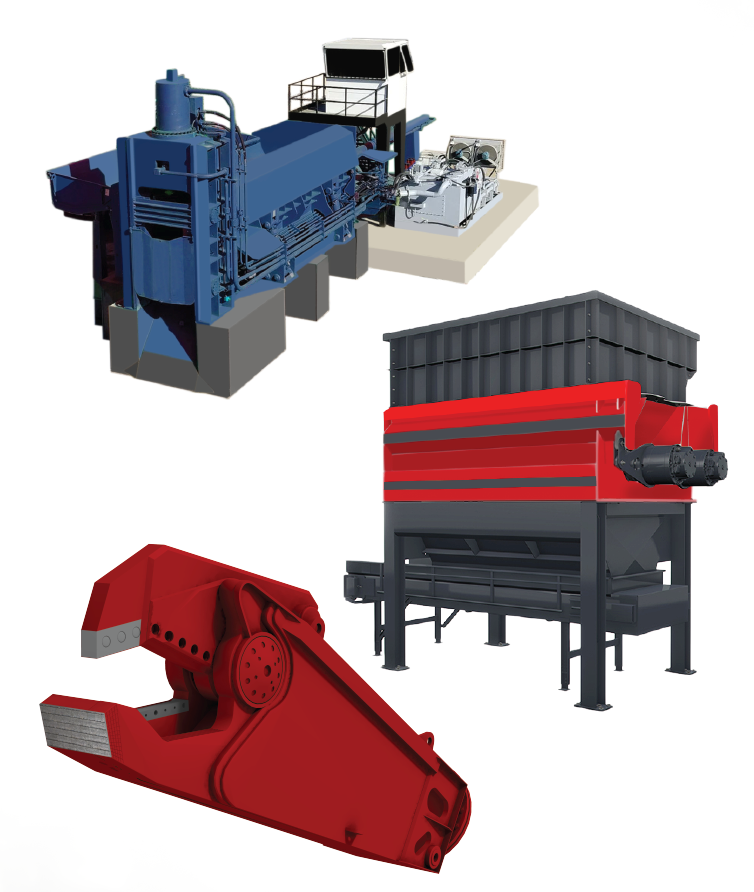

Bailer, Shear & Pre-Shredder Components

- Liners and wear plates engineered to withstand compression, shearing, and heavy abrasion

- Custom-fit for longer service life and simplified installation

Material Handling & Processing Components

- Wear-Resistant Chutes, Hoppers, and Transfer Liners

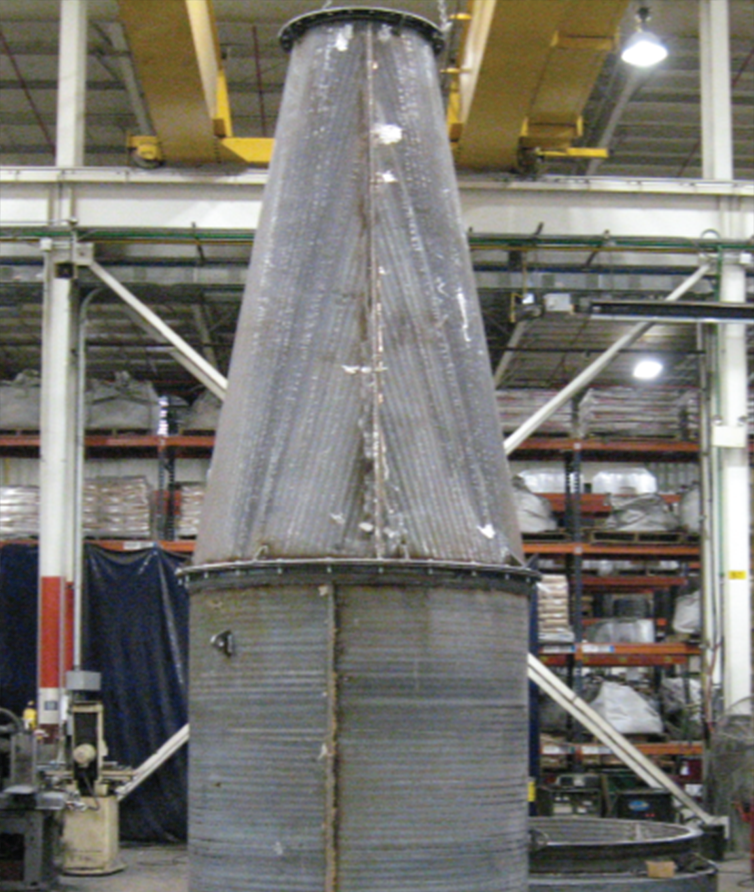

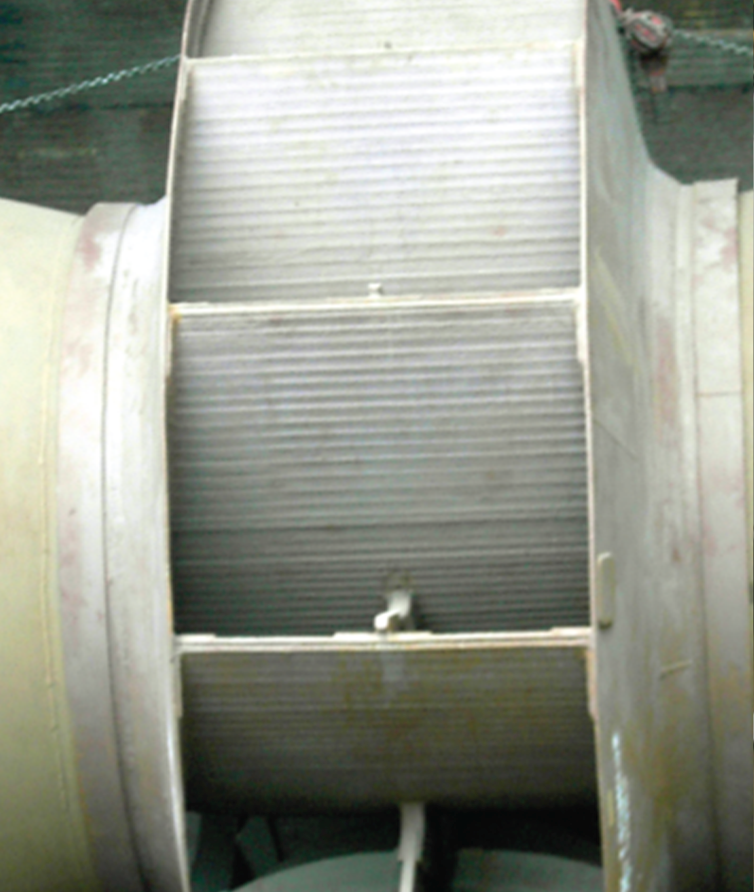

- Cyclones, Fans, and Fan Housings – built for airflow, impact, and material wear

- Fabricated & Cladded Pipe Systems – internal wear-resistant surfaces for extended life in abrasive material flow

What You Gain:

- Extended Equipment Life

- Fewer Maintenance Interruptions

- Improved Throughput

- Lower Cost Per Ton Processed

If you’re processing scrap, SAS Global protects the systems that power your plant so you can focus on throughput, not downtime.

Explore a specific SAS Metal Recycling Industry Component or Service Below:

Mobile Mining Equipment Solutions

Mega / Auto Shredder Wear Resistant Components

Mining On-Site Installation & Repair

Bailer, Shear, Pre-Shredder Wear Resistant Solutions

Wear Resistant Chute, Hoppers and Liner Systems

Cylcones - Premium Wear Resistant

Wear Resistant Fans and Housing Solutions

Underground Mining Solutions

Premium Wear Resistant Trommels

Premium Wear Resistant Piping

Premium Wear Resistant Piping - Fabricated Carbide Overlay or Hardfaced Cladded Options

Premium Wear Resistant Materials

Premium Wear Resistant Materials