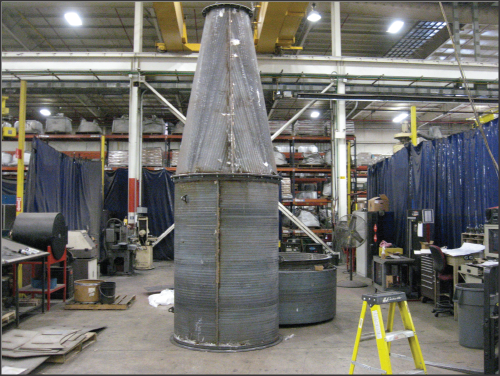

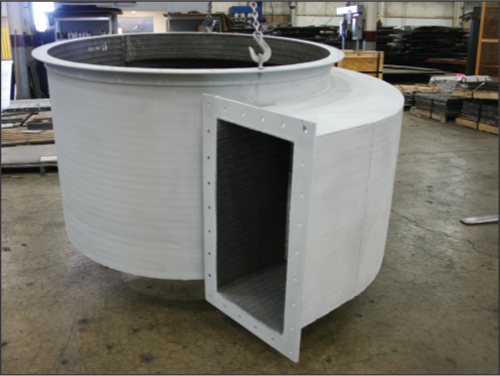

WEAR RESISTANT CYCLONES & LINER SYSTEMS

Comprehensive Wear Protection | Engineered for Extended Service Life

SAS Global’s Wear-Resistant Cyclones and Cyclone Liner Systems are custom-engineered to deliver exceptional abrasion resistance, enhanced efficiency, and maximum equipment longevity. Built for high-wear environments in cement, mining, and processing operations, our cyclones are fabricated using industry-leading premium materials that dramatically reduce maintenance and replacement cycles.

Engineered to Outlast & Outperform

- Extended Service Life – Built from SAS’s most advanced wear-resistant alloys for long-term durability

- Maximum Performance – Optimized internal surfaces improve flow efficiency and reduce turbulence

- Custom-Fit Solutions – Cyclones and liners are tailored to meet your specific equipment dimensions and process needs

- Lower Maintenance Costs – Fewer replacements, reduced downtime, and consistent operation

Available Premium SAS Global Material Options:

- SA6000® – Patented Microstructure Complex Carbide Overlay Plate offering unmatched abrasion and impact resistance

- SA2000® – Premium Complex Carbide Overlay Plate with enhanced toughness for demanding wear conditions

- SA1750CR® – Industry-trusted Chromium Carbide Overlay Plate for consistent performance in abrasive applications

- Vanguard® Alloy Wear Plate (460/540 HB) – Through-hardened alloy plate providing excellent impact and sliding wear resistance

Common Applications:

- Cement & Raw Material Processing

- Mineral Separation & Classification

- Dust Collection Systems

- Grinding & Pulverizing Circuits

Upgrade your cyclone performance with SAS Global’s Premium Wear-Resistant Cyclones and Liners—built for durability, engineered for results.