SUGAR CANE INDUSTRY: SOLUTIONS FOR WEAR, PROCESS & EQUIPMENT

Engineered for Durability | Built to Extend Equipment Life | Proven to Reduce Downtime

Sugar cane processing presents a unique set of wear challenges—from fibrous abrasion to high-moisture corrosion. SAS Global partners with sugar mills and processors to deliver reliable wear protection solutions that extend component life, reduce maintenance frequency, and keep your operation running at peak efficiency.

Our wear-resistant products are fabricated using SAS-engineered premium materials like SureAlloy® Carbide Overlay and Vanguard® Alloy Wear Plate, offering unmatched durability in harsh process environments. Whether it's rebuilding high-wear parts or fabricating new components, SAS Global delivers proven results.

Solutions That Protect & Perform:

- Component Rebuilding with Hardfacing: Restore worn parts with longer-lasting materials

- Wear-Resistant Liners & Plates: Custom-fitted for chutes, hoppers, screw conveyors, and crushers

- Premium Materials for New Fabrications: Designed to withstand the constant abrasion and impact of sugarcane fiber, mud, and juice

Key Benefits for Sugar Processors:

- Increase Service Life: Fewer changeouts and reduced part failure

- Reduce Maintenance Downtime: Less time in the shop, more time in production

- Lower Operational Costs: Minimize maintenance labor and replacement frequency

- Boost Plant Reliability: Improve flow consistency and minimize wear-related shutdowns

If you’re processing sugarcane, SAS Global protects the equipment that powers your production—delivering more uptime and more value with every cycle.

Explore a specific SAS Sugar Cane Processing Industry Component or Service Below:

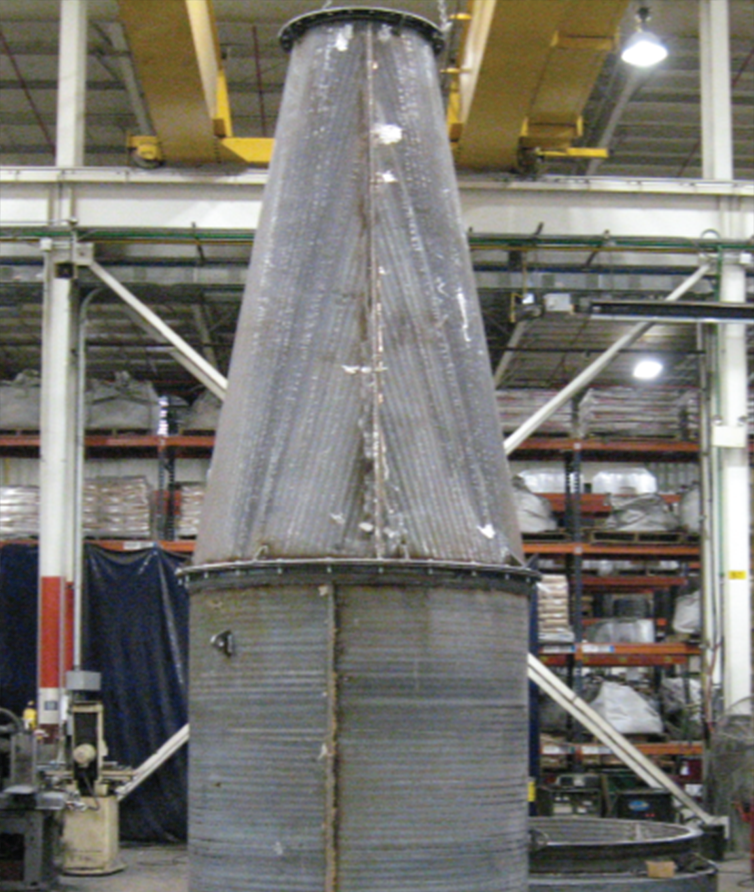

Cylcones - Premium Wear Resistant

Wear Resistant Chute, Hoppers and Liner Systems

Wear Resistant Fans and Housing Solutions

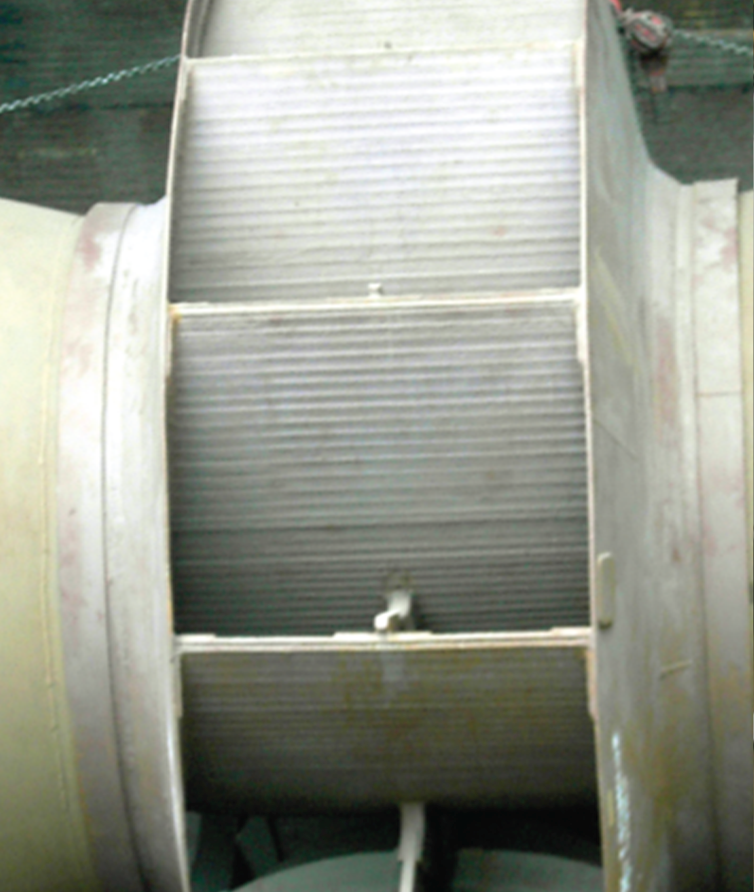

Premium Wear Resistant Piping

Premium Wear Resistant Piping - Fabricated Carbide Overlay or Hardfaced Cladded Options

Premium Wear Resistant Materials

Premium Wear Resistant Materials