DREDGING INDUSTRY: SOLUTIONS FOR WEAR

Engineered for Extreme Abrasion | Proven to Extend Life | Built to Boost Productivity

Dredging operations demand equipment that can handle the harshest materials—abrasive sand, rock, and silt with coarse granularity and sharp edges. SAS Global delivers field-proven wear solutions engineered to perform where conventional materials fail. Our proprietary SureAlloy® Premium Carbide Overlay materials are designed to combat excessive wear, reduce downtime, and significantly cut maintenance costs.

Engineered for Your Most Demanding Applications:

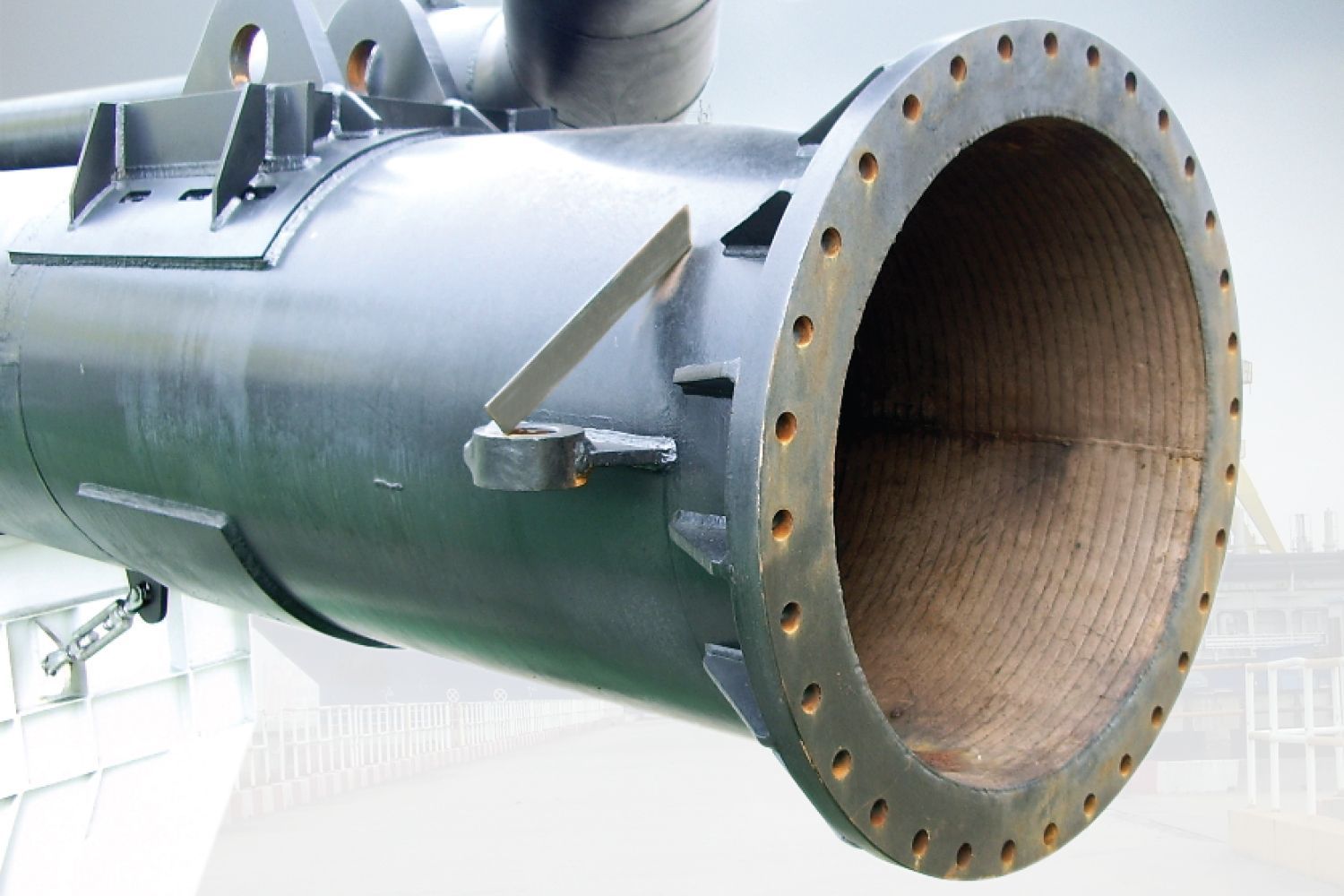

- Suction & Submerged Pipelines – Fabricated directly from SureAlloy® for superior internal abrasion resistance

- Pump Wear Rings

- Pump Discharge & Shore Discharge Liners – Built to withstand continuous impact and abrasive slurry flow

- Floating Pipelines – Reinforced for long-term exposure in dynamic environments

Other SAS Dredging Solutions Include:

- Cargo Hold & Hopper Liners

- Cutter-Head Liners

- Clamshell Buckets & Liner Systems

- Dredge Pipe Sections

- Shore-Based Transfer Points & Elbows

Your Benefits at a Glance:

- Longer Component Life = Fewer Changeouts

- Reduced Downtime = More Dredging Time

- Lower Maintenance Costs = Improved Project ROI

- Engineered for Fit = Faster Installs and Retrofits

Whether you're cutting through clay, sand, or rock—SAS Global’s SureAlloy® materials are proven to hold up when other wear solutions fail. Protect your pumps, pipelines, and payload areas with dredging wear solutions designed for performance, built for endurance.

SUCTION PIPELINE: Directly fabricated from SureAlloy Premium Carbide Overlay Plate

PUMP WEAR RING: Directly fabricated from SureAlloy Premium Carbide Overlay Plate

OTHER WEAR RESISTANT COMPONENTS FROM SAS GLOBAL

- Cargo Hold Hopper Area Liners

- Cutter-Head Liners

- Clamshell Buckets and Liners

- Dredge Pipes

- Floating Pipelines

- Pump Discharges

- Shore Discharge Liners

- Submerged Pipelines

- Suction Pipelines