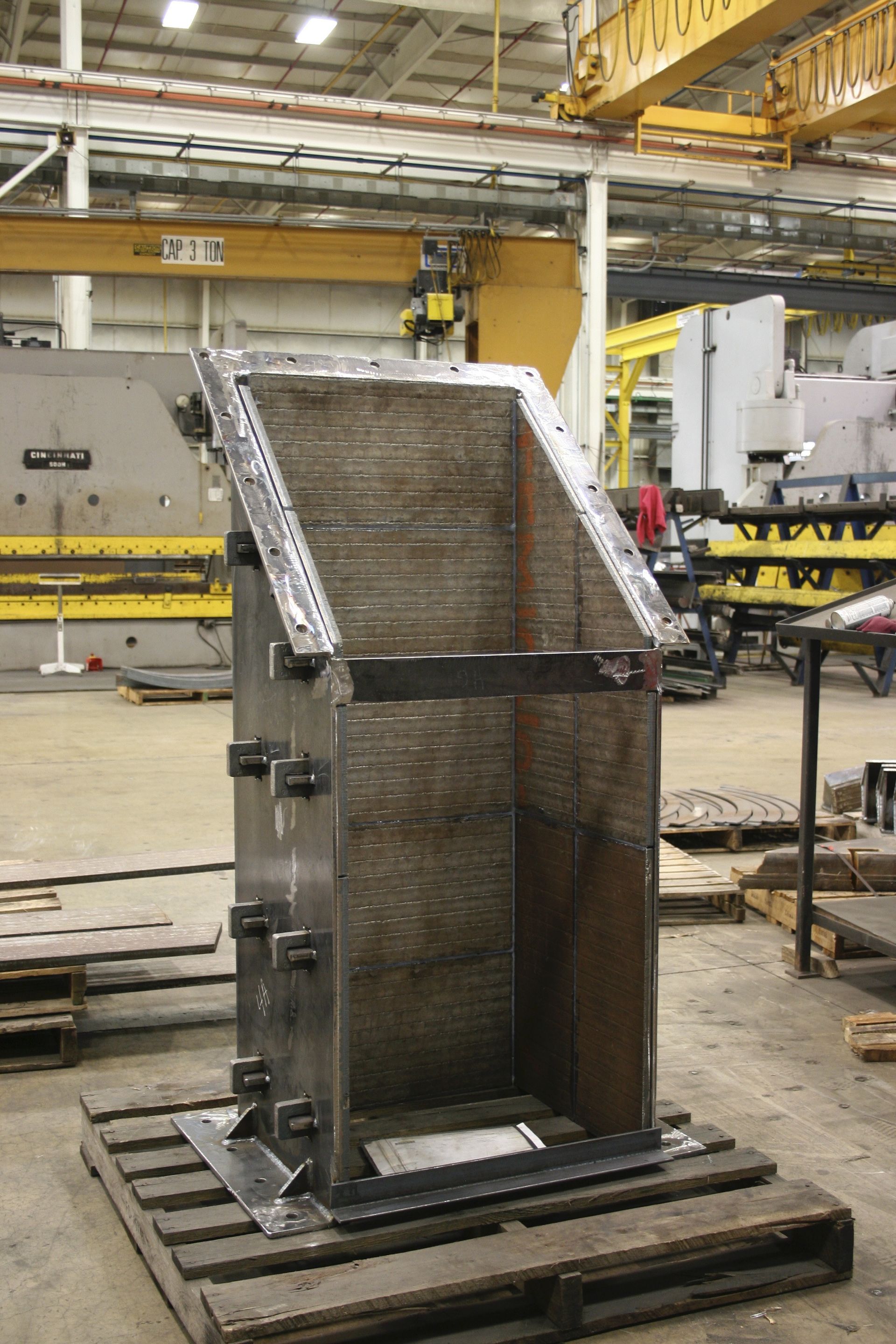

BASIC OXYGEN FURNACE (BOF) COMPONENTS

Engineered for Maximum Service Life | Custom-Fabricated for Durability & Precision Fit

SAS Global manufactures high-performance wear resistant components for Basic Oxygen Furnace (BOF) operations, delivering extended equipment life, improved system reliability, and reduced maintenance costs. Each component is custom designed to fit your system and fabricated using the most advanced wear-resistant materials available—ensuring optimal performance in high-heat, high-abrasion BOF environments.

Partial BOF Component Application List:

- Scrap Boxes / Scrap Cars

- Scrap Car Liners

- Raw Material Hoppers & Chutes

- Alloy Hoppers

- Reverse Fan Air Boxes

- Baghouse Liners

- Cyclones & Cyclone Liners

Why Choose SAS Global for BOF Components?

- Longer Component Life: Engineered to withstand high wear, thermal stress, and impact

- Reduced Maintenance Downtime: Fewer changeouts and more uptime

- Custom-Fit Designs: Precision-engineered to match your equipment specs

- Field-Proven Performance: Trusted by steel producers and heavy industry operations worldwide

Available Premium SAS Global Material Options:

- SA6000®: Patented Microstructure Complex Carbide Overlay Plate for extreme wear and impact resistance

- SA2000®: Premium Complex Carbide Overlay Plate with enhanced toughness

- SA1750CR®: Chromium Carbide Overlay Plate designed for aggressive abrasion

- Vanguard® Alloy Wear Plate (460/540 HB): Through-hardened alloy with high impact resistance

- SA400 Alloy Wear Plate (360/440 HB): A reliable option for moderate-to-heavy wear environments

- Ceramics: Ideal for fine particulate and severe abrasion protection

- Tungsten Carbide: Maximum hardness for the most demanding wear zones

When it comes to BOF reliability and wear resistance, SAS Global provides custom-engineered solutions that last longer and perform better.