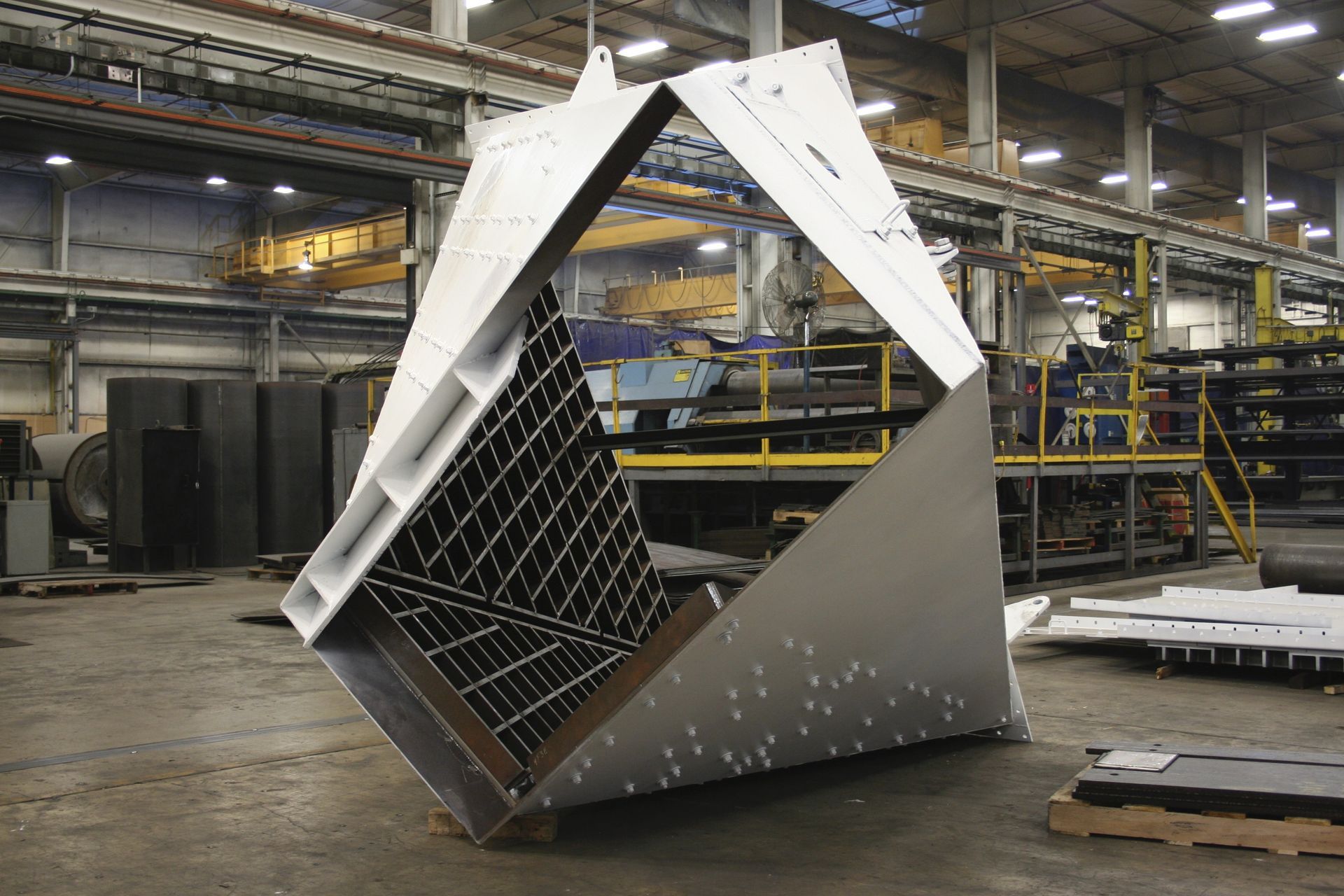

DIRECT REDUCED IRON (DRI) PROCESS COMPONENTS

Built for Maximum Durability | Extended Service Life | Engineered for Demanding Applications

SAS Global provides high-performance wear-resistant solutions tailored for the Direct Reduction Iron (DRI) industry. From raw material handling to furnace feed systems, SAS designs each product for maximum durability, reduced maintenance, and optimal performance—even in the most abrasive and high-temperature applications.

Our components are fabricated from premium wear-resistant materials and custom-engineered to your operational requirements, ensuring reliable performance and long-term cost savings.

Partial Application List for DRI Operations:

- Wear-Resistant Liners

- Raw Material Hoppers & Chutes

- Transfer Chutes & Surge Bins

- Cones & Diverter Plates

- Furnace Feed Pipes

- Conveyor Skirtboard Liners

- Fan Blades & Fan Housings

- Baghouse Liners

- Cyclones & Cyclone Liners

- Clamshell Liners & Rebuilds

Why SAS Global for DRI Wear Protection?

- Extended Component Life: Built to resist extreme abrasion, impact, and thermal stress

- Minimized Downtime: Longer-lasting parts mean fewer replacements and less unplanned maintenance

- Precision Fit & Fabrication: Custom-built to match your system requirements for seamless integration

- Field-Tested Performance: Trusted by leading DRI producers for reliable, long-term results

Available SAS Global Premium Material Options:

- SA6000®: Patented Microstructure Complex Carbide Overlay Plate for extreme abrasion and impact resistance

- SA2000®: Premium Complex Carbide Overlay Plate combining toughness and long wear life

- SA1750CR®: Proven Chromium Carbide Overlay Plate for consistent protection in abrasive loading conditions

- Vanguard® Alloy Wear Plate (460/540 HB): Through-hardened steel for high impact and sliding wear

- SA400 Wear Plate (360/440 HB): Durable, cost-effective wear plate for moderate to heavy-duty applications

SAS Global’s DRI wear-resistant solutions deliver the performance, protection, and reliability your operation demands—engineered to keep your production running longer and stronger.