MINING INDUSTRY: SOLUTIONS FOR WEAR, PROCESS & EQUIPMENT

Extend Equipment Life | Improve Operational Performance | Reduce Downtime

SAS Global is your single-source solution for high-performance wear protection, process optimization, and equipment reliability. Unlike standard suppliers, SAS Global not only fabricates components—we engineer and manufacture our own premium wear-resistant materials, ensuring each solution is precisely tailored to meet your specific operational needs and specifications. All manufactured in the USA.

What Sets SAS Global Mining Apart:

- In-house material development – SAS creates its own advanced wear-resistant alloys for superior performance.

- Precision fabrication – Every liner system and processing component is engineered for your specific equipment and environment.

- Turnkey solutions – From material development to final installation, SAS provides full-service mining wear protection.

Engineered Solutions for Mining Operations:

- High-Performance Liner Systems – Designed to protect chutes, hoppers, crushers, and material handling systems from extreme abrasion and impact.

- Custom Processing Components – Built to handle the toughest mining conditions while improving flow, efficiency, and service life.

- Extended Equipment Lifespan – Reduce unplanned downtime, minimize maintenance, and lower replacement costs.

- Improved Operational Efficiency – Optimize material movement and reduce energy usage with engineered wear solutions.

For unmatched durability, custom-engineered protection, and industry-proven performance—trust SAS Global Mining to keep your operation moving.

Explore a specific SAS Mining component or service below:

Mobile Mining Equipment Solutions

Liner Systems: Truck Beds, Dozer Blades, Front End Loaders, Shovel Buckets, Dragline Buckets, Graders

Processing & Material Transfer Equipment

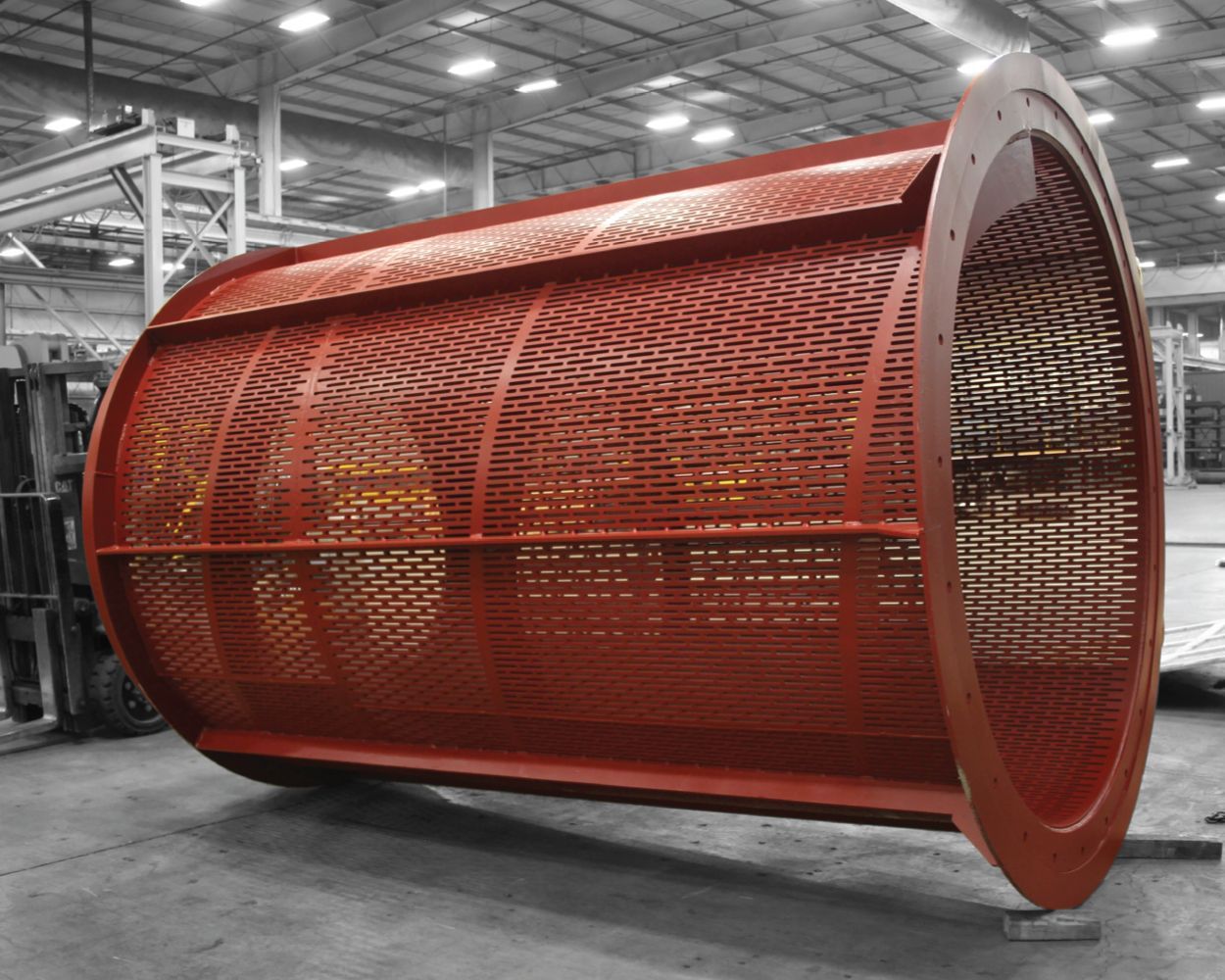

Chutes | Hoppers | Trommels | Crusher Components | Liners | Grates

Mining On-Site Installation & Repair

Equipment Liner Installation | Equipment Repair Services

Underground Mining Solutions

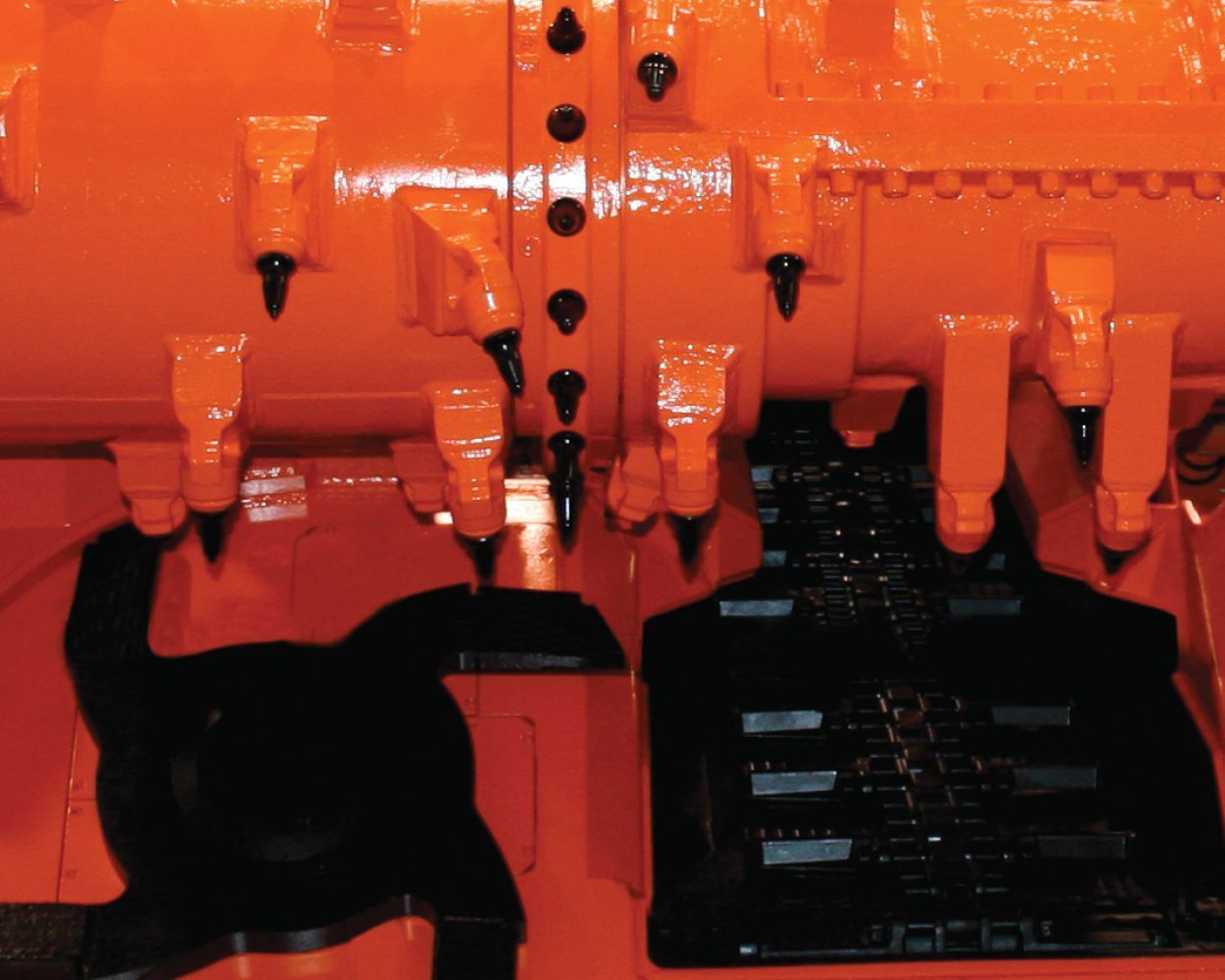

Continuous Miner Components & Liners | Deck Plates | Gathering Pans | Crawler Track Wear Runner

Premium Wear Resistant Materials

SureAlloy Carbide Overlay Plate | Vangaurd Premium Alloy Wear Plate | SA400 | Hardfacing

Premium Wear Resistant Piping

Fabricated Carbide Overlay or Hardfaced Cladded Options