MINING EQUIPMENT REPAIR & INSTALLATION SERVICES

An Experienced & Dependable Approach to Your Mining Equipment Repair Needs

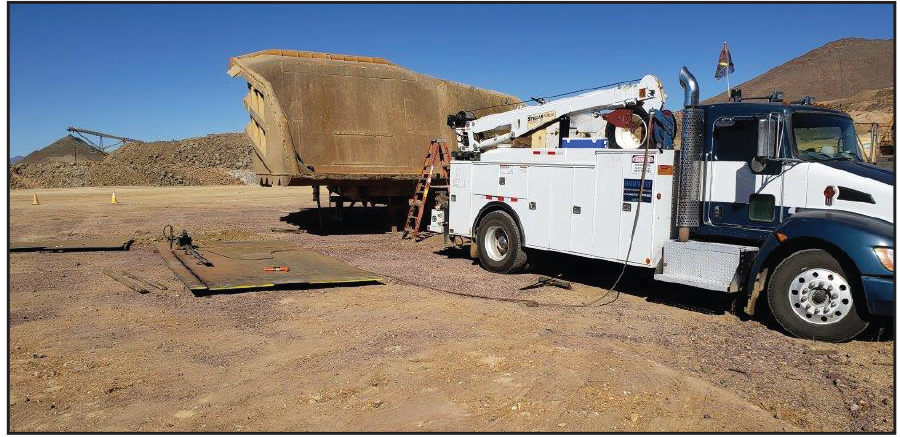

SAS Global delivers comprehensive mining equipment repair, upgrade, and installation services—whether on-site or in-plant. Backed by decades of field-proven expertise and a reputation for reliability, SAS offers a full-service approach designed to extend the life of your equipment, minimize downtime, and restore peak performance with premium-grade materials and expert craftsmanship.

Mobile On-Site Services:

- Component System Upgrades & Replacements – Precision-engineered upgrades to extend equipment life

- Wear Liner System Removal & Installation – Complete liner changeouts using SAS wear-resistant solutions

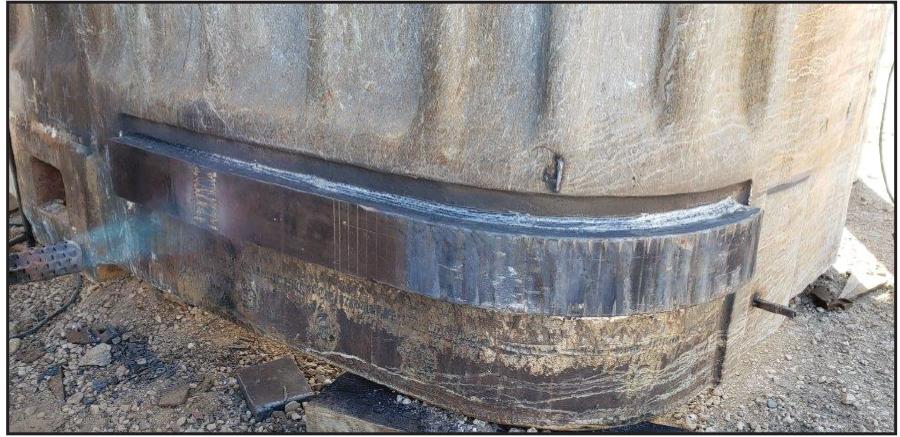

- Structural Repair – Heavy-duty welding and fabrication for compromised components

- Field Machining – On-site milling, cutting, and finishing for critical fits

- Line Boring – Precision alignment and bore restoration

- Weld Repair – Expert welding to restore structural integrity

- Complete Fabrication – From single components to complex rebuilds, done at your site

In-Plant Maintenance Services:

- Supplemental Skilled Labor – Professional teams to support your maintenance shutdowns and ongoing repairs

- Piping Systems – Installation and repair of abrasion-resistant steel or carbide overlay plate piping

- Transfer Chute Systems – Repairs, upgrades, and turnkey installations of custom-engineered chutes

- Mill & Crusher Liners – Hardfacing and installation services to enhance performance and extend component life

Why SAS Global?

- On-demand mobile services to reduce downtime

- Turnkey capabilities from design through installation

- Premium SAS wear-resistant materials for long-term results

- Decades of mining industry experience you can trust

When uptime matters, SAS Global delivers expert repair and installation services—wherever and whenever you need them.