MATERIAL / FUEL HANDLING & PROCESSING SOLUTIONS

Increase Production | Reduce Downtime | Eliminate Material Hang-Up | Reduce Dust

SAS Material & Fuel Handling Solutions: Engineered for Maximum Efficiency & Durability

SAS Global provides high-performance material and fuel handling solutions designed to optimize production, reduce maintenance, and eliminate common material flow issues. Our advanced systems and patented technologies ensure smooth material handling, enhanced wear resistance, and increased operational efficiency in high-wear environments.

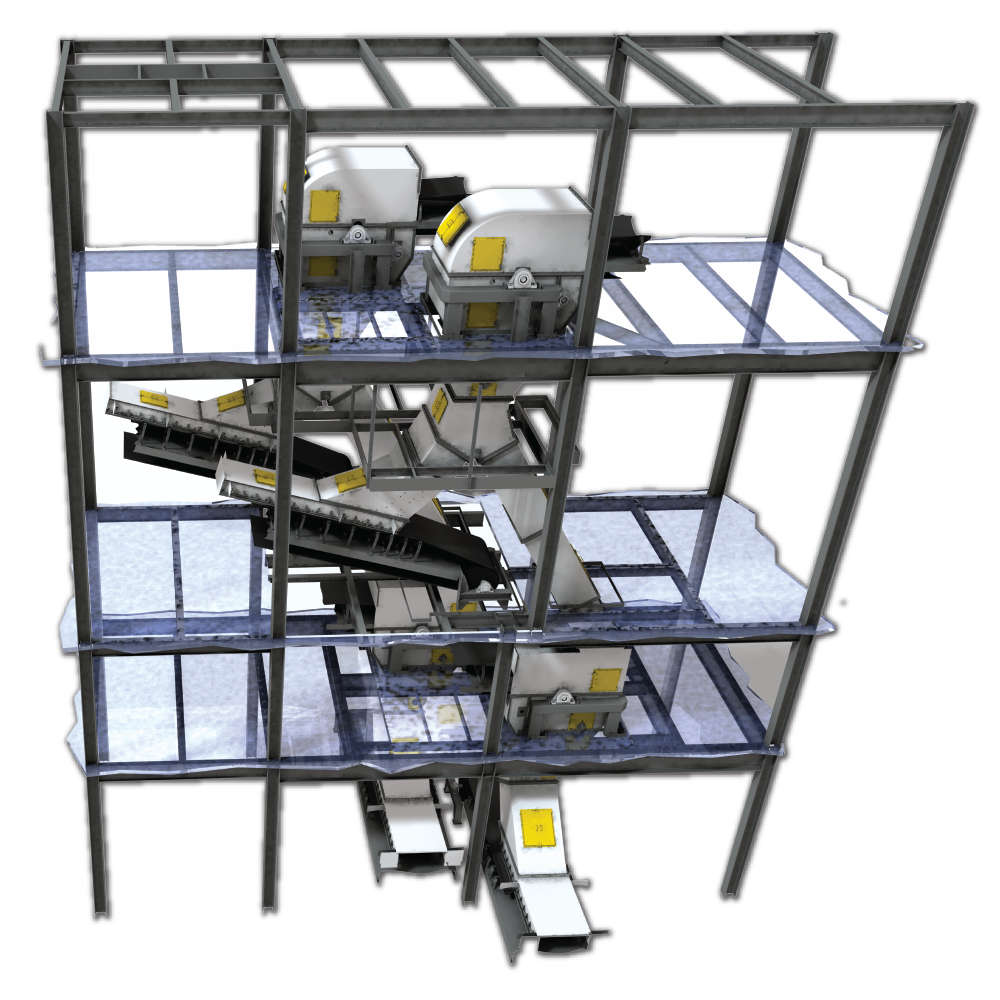

Industry-Leading Handling & Processing Solutions

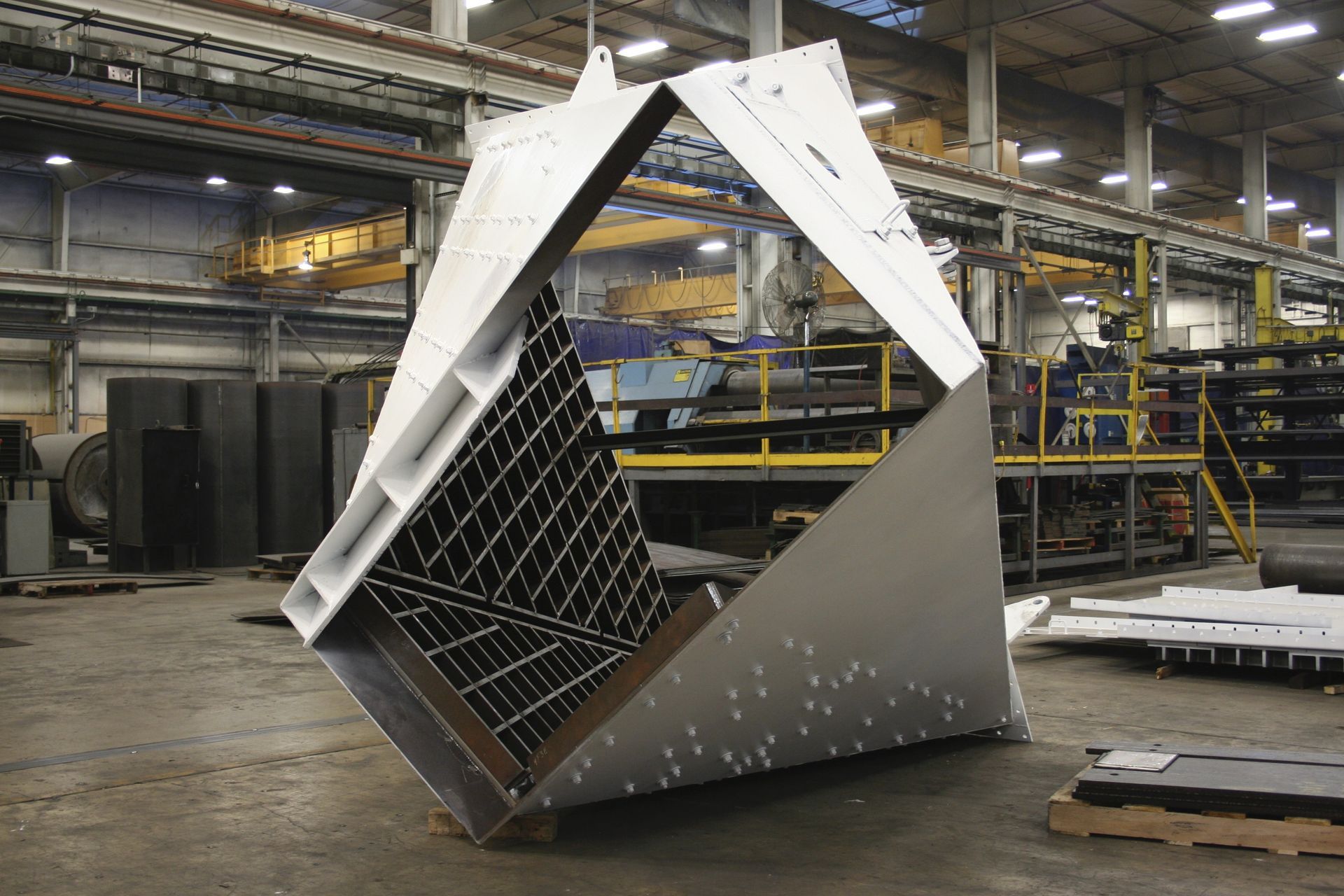

- Controlled Flow Chute Systems – Engineered for optimized material movement, preventing blockages and reducing wear.

- Premium Chutes & Hoppers – Constructed from SureAlloy® Premium Carbide Overlay Plate for long-lasting durability.

- Patented Self-Cleaning Coal Sizing Grid – Eliminates unnecessary crushing of coal, reducing crusher maintenance.

- Patented Debris Separator – Effectively removes unwanted material, protecting downstream equipment from damage.

- Hammer Mill Modernization Screen System – Extends hammer mill service life and improves screening efficiency.

- Crusher Screens & Hammers – Precision-engineered for high impact and abrasion resistance, reducing replacement frequency.

Optimized for Performance & Reliability

- Enhanced material flow, reducing hang-ups and downtime.

- Extended component life, minimizing maintenance costs.

- Improved dust control, creating a safer and cleaner work environment.

Upgrade your material handling systems with SAS Global’s advanced solutions—built for efficiency, durability, and long-term performance.