CONTROLLED FLOW TRANSFER CHUTE SYSTEMS

Engineered for Improved Flow | Eliminate Material Hang-Up | Reduce Dust

Engineered for Optimal Material Handling

With over 70 years of expertise in wear-resistant solutions, SAS Global designs Controlled Flow Transfer Chute Systems to ensure optimal material flow, minimize hang-ups, and reduce dust creation. Our chutes are constructed from premium materials to provide the longest possible service life.

Key Benefits of SAS Global Chute Systems:

- Improved Material Flow: Engineered designs promote seamless material movement, reducing blockages and enhancing operational efficiency.

- Elimination of Material Hang-Ups: Low-friction surfaces and proper flow engineering prevent material buildup, ensuring continuous flow and reducing downtime.

- Dust Reduction: Optimized chute designs minimize dust generation, contributing to a cleaner and safer work environment.

- Extended Service Life: Utilization of premium wear-resistant materials ensures durability and longevity, decreasing maintenance frequency and costs.

Premium Material Options for Extended Service Life:

- SA6000® Patented Microstructure Complex Carbide Overlay Plate

- SA2000® Premium Complex Carbide Overlay Plate

- SA1750CR® Premium Chromium Carbide Overlay Plate

- RapidFlow® Premium Smooth Finish Carbide Overlay Plate

- Vanguard Premium Alloy Wear Plate (460/540 HB)

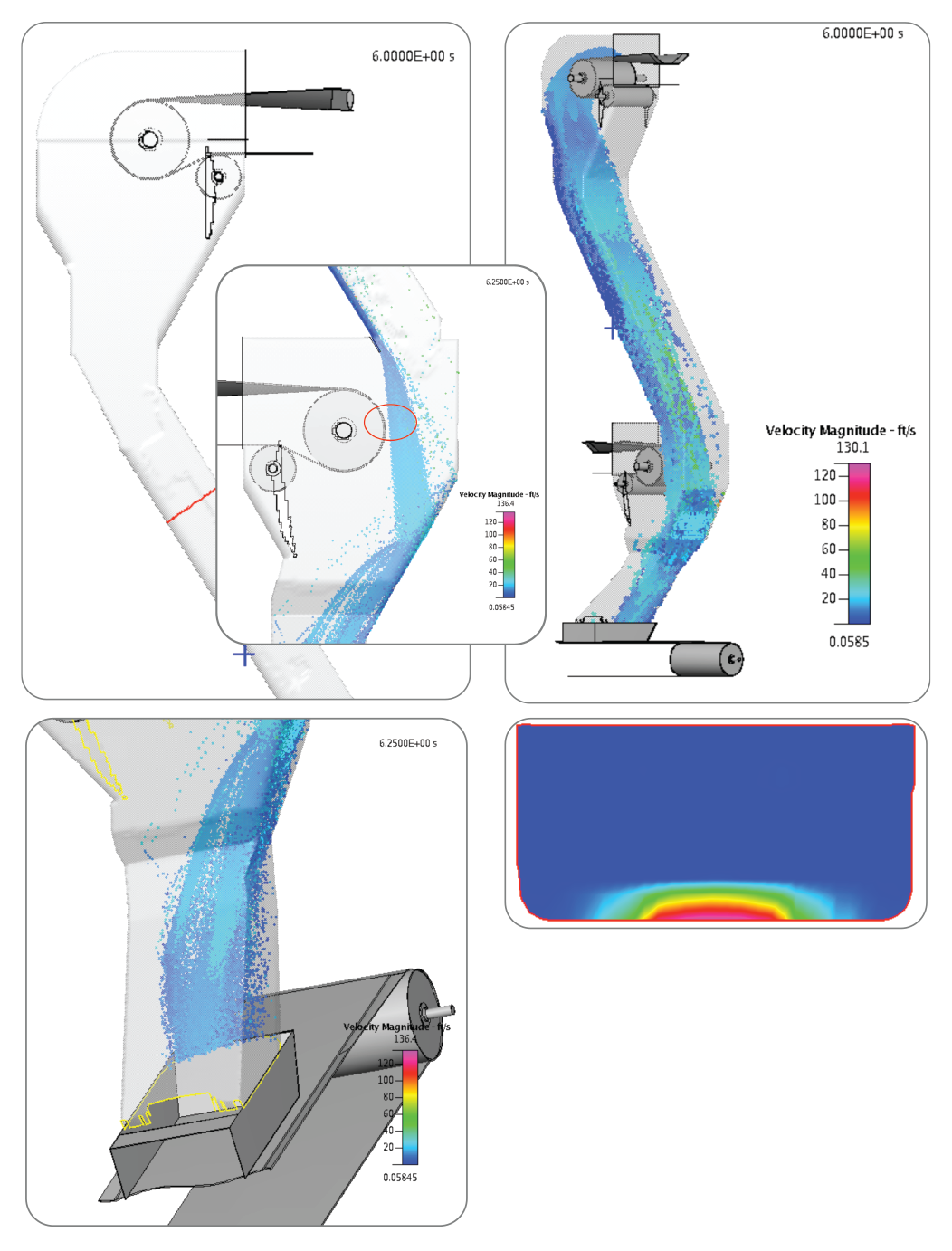

Example SAS Controlled Flow Chute System:

All chutes and skirt boxes were engineering, fabricated and installed by SAS Global.