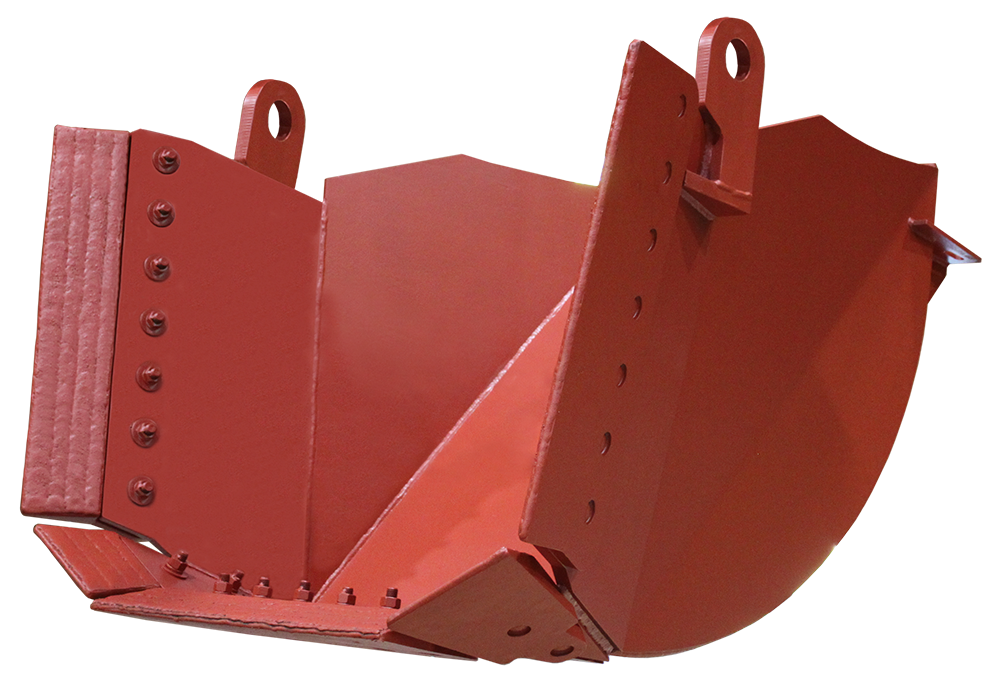

WEAR RESISTANT WHEEL LOADER BUCKETS & CLAMSHELLS

Built for Maximum Durability | Extended Service Life | Engineered for Demanding Applications

SAS Global designs and manufactures high-performance wheel loader and clamshell buckets, along with custom wear-resistant liner systems that deliver exceptional longevity and reliability in high-impact, high-abrasion environments. Whether for mining, aggregate, cement, or bulk material handling, these buckets are engineered for superior performance, minimal downtime, and unmatched protection.

Performance Highlights:

- Extended Service Life: Fabricated from SAS premium wear-resistant materials to dramatically reduce wear & replacement cycles

- Optimized Bucket Flow: Low-friction liner surfaces help reduce carryback and improve material release

- Custom Fit: Tailored designs for new builds or retrofits to existing buckets

- Reduced Downtime: Longer-lasting components mean fewer interruptions and lower maintenance costs

Common Applications:

- Wheel Loader Buckets

- Clamshell Buckets

- Bulk Material Transfer

- Mining, Steel, Cement, and Aggregate Environments

Available SAS Global Premium Material Options:

- SA6000® – Patented Microstructure Complex Carbide Overlay Plate for extreme abrasion and impact resistance

- SA2000® – Premium Complex Carbide Overlay Plate combining toughness and long wear life

- SA1750CR® – Proven Chromium Carbide Overlay Plate for consistent protection in abrasive loading conditions

- Vanguard® Alloy Wear Plate (460/540 HB) – Through-hardened steel for high impact and sliding wear

- SA400 Wear Plate (360/440 HB) – Durable, cost-effective wear plate for moderate to heavy-duty applications

When your buckets need to last longer, work harder, and reduce downtime—SAS Global delivers industry-leading wear solutions that keep your operation moving.