THE SMARTER SOLUTION FOR EXTREME WEAR ENVIRONMENTS

Premium 500 Brinell Alloy Steel Wear Plate | Premium AR500

When it comes to heavy-duty applications, wear resistance isn’t just a feature—it’s a necessity. That’s why SAS Global developed Vanguard Alloy Wear Plate, an advanced AR500 material engineered to withstand the most punishing conditions.

Vanguard is a water-quenched, through-hardened martensitic steel that delivers superior impact and abrasion resistance. Its homogeneous hardness, achieved through a specialized quenching and tempering process, ensures long-lasting durability without the brittleness found in conventional options. Additionally, Vanguard’s low phosphorus and sulfur content enhances its strength and toughness, reducing the risk of premature failure in high-stress applications.

What does this mean for your operation? Vanguard outlasts AR400 by 2 to 3 times, allowing for thinner, lighter wear liners that maintain strength while reducing weight and downtime. Whether you're working with chutes, hoppers, or high-impact equipment, Vanguard extends service life, minimizes maintenance, and maximizes efficiency—keeping your operation running smoothly.

Stronger. Tougher. Longer-lasting. Vanguard Alloy Wear Plate is the smart choice for those who refuse to compromise on performance.

Advantages

- Through hardened for extra long service life

- Long service life equates to less downtime

- 460 to 540 Brinell Hardness

- High abrasion and impact resistance

- Low Phosphorus and Sulphur content

- Low Carbon Content

- High Chrome Content

- Fine-Grain, Hard Microstructure

Available Thicknesses (stock plate: 96" x 288")

- 1/4" through 2"

- 2.5"

- 3"

- Custom cut plate sizes available on request

Common Applications

- Chute Liners

- Hoppers

- Crusher Screens

- Trommel Screens

- Primary Scalping Beams

- Truck Bed Liners

- Shovel Bucket Liners

- Vibratory Feeder Liners

- Impact Plates

- Deck Plates

- Sigma Rails

- Elevator Buckets

- Clamshell Bucket Liners

- Quench Cars

- Coke Pusher Face & Doors

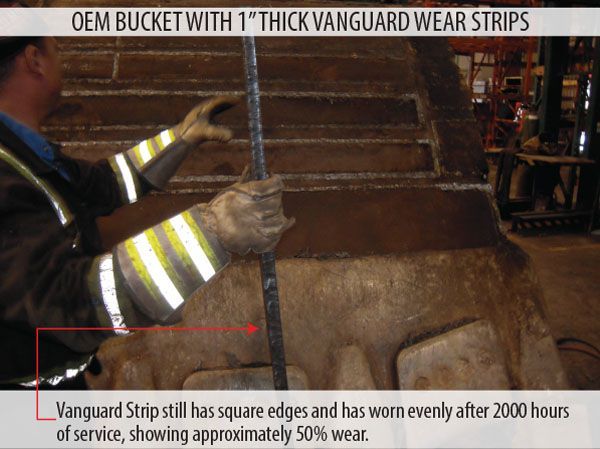

Bucket Wear Strip Case History:

Vanguard Out Performs Brand X with 4X the Life!

In high-wear industries, equipment downtime is a costly reality. At an Iron Ore Mine, a direct comparison between Brand X wear strips and SAS Vanguard Premium Alloy Wear Plate revealed a game-changing advantage in durability and efficiency.

The Problem

A CAT 930 bucket fitted with 1” thick Brand X wear strips lasted only 1,200 hours before severe wear exposed and damaged the bucket’s parent metal. Extensive repairs and new wear strips were required, adding to maintenance costs and downtime.

The Vanguard Advantage

A second CAT 930 bucket, protected with SAS Vanguard Alloy Wear Plate strips, was kept in service for 2,000 hours at the same mine. Upon inspection, the Vanguard strips showed only 50% wear at most, proving their superior resistance to abrasion and impact.

The Results

Buckets using Brand X wear strips required rebuilding every 3 months, leading to frequent disruptions. In contrast, buckets protected with 1” thick Vanguard Wear Strips lasted nearly a year before replacement was needed—up to 4X the lifespan!

By switching to Vanguard Alloy Wear Plate, maintenance teams can significantly reduce downtime, lower repair costs, and increase operational efficiency. When durability matters, Vanguard delivers where others fail.