UNDERGROUND MINING WEAR RESISTANT SOLUTIONS

Engineered for Maximum Durability | Extended Service Life | Proven Underground Performance

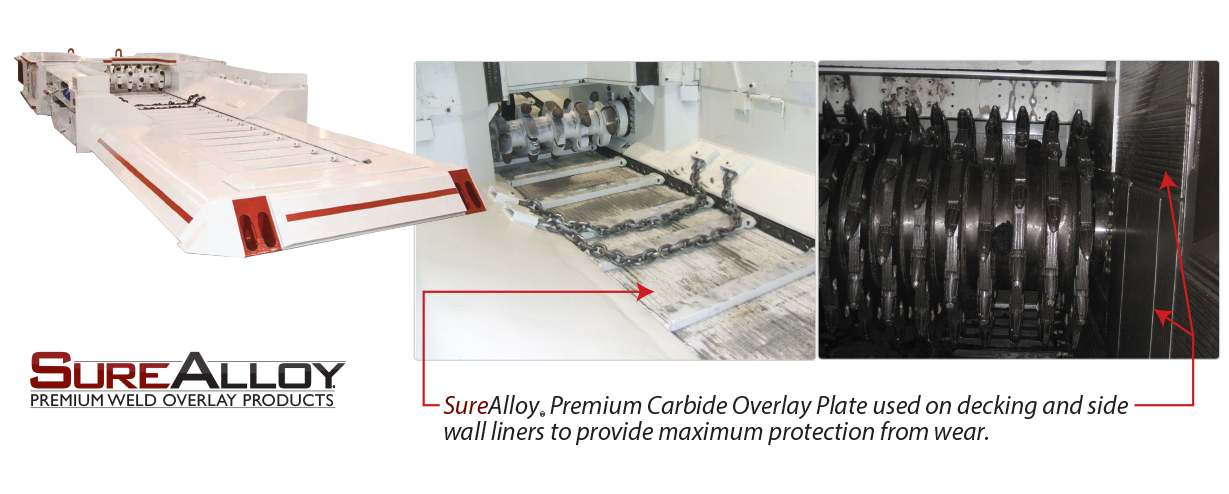

SAS Global provides high-performance wear-resistant components and liners specifically engineered for the harsh conditions of underground mining operations. Utilizing SureAlloy® Premium Carbide Overlay Plate and Vanguard® Alloy Wear Plate, SAS delivers long-lasting solutions that minimize downtime, reduce maintenance, and enhance the operational lifespan of critical equipment.

Built to Perform Underground:

- Extended Service Life – Premium materials resist abrasion, impact, and extreme wear

- Increased Uptime – Fewer replacements and less downtime keep operations moving

- Application-Specific Designs – Engineered to meet the unique challenges of underground mining environments

- Custom Fabrication – Manufactured to your specs for a precise fit and optimal performance

Common Underground Mining Applications:

- CLA Shoes – Built tough for crawler movement and high-friction surfaces

- Continuous Miner Components – Reinforced with SAS materials for long-lasting mining efficiency

- Deck Plates – Withstand heavy abrasion while supporting constant load movement

- Sigma Rails – Engineered for structural integrity and long wear life

- Gathering Pan Liners – Reduce material hang-up and surface wear

- Discharge Conveyor Deck Liners – Protect conveyor infrastructure from material wear

- Crawler Track Wear Runners – Reduce maintenance cycles and increase track durability

Premium Wear-Resistant Materials from SAS Global:

- SureAlloy® Premium Carbide Overlay Plate – Maximum abrasion resistance for extreme wear zones

- Vanguard® Premium Alloy Wear Plate (460/540 HB) – Through-hardened steel for impact and wear protection in demanding environments

For underground mining operations that demand performance and longevity, SAS Global delivers wear-resistant solutions engineered to outlast and outperform.