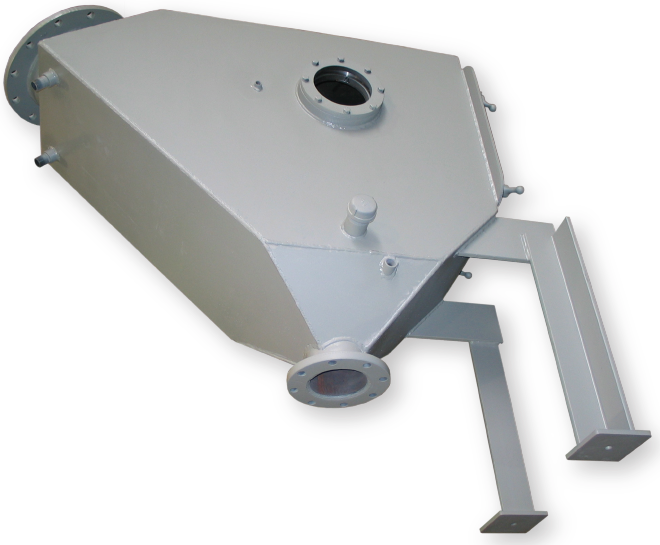

PYRITE HOPPERS | PREMIUM WEAR LIFE

Fabricated From Premium Wear Resistant Materials for Extended Service Life

Custom-Engineered for Maximum Wear Life

SAS Global Premium Pyrite Hoppers are built to meet your exact specifications and service life goals, providing superior protection in the most abrasive operating environments. Each hopper is custom-fabricated using the optimal wear-resistant material for your specific application and fuel type—delivering longer service life and reduced maintenance downtime.

Material Options to Match Your Needs

SAS Global offers a full range of high-performance materials, ensuring the best possible solution for your operation:

- SA6000® Patented Microstructure Complex Carbide Overlay Plate

Unmatched abrasion resistance with a proprietary microstructure—ideal for the harshest conditions. - SA2000® Premium Complex Carbide Overlay Plate

Engineered for severe wear environments requiring a balance of abrasion and moderate impact resistance. - SA1750CR® Premium Chromium Carbide Overlay Plate

Proven protection in high-abrasion applications, with reliable performance and cost efficiency. - Vanguard Alloy Wear Plate (460/540 HB Through-Hardened)

Exceptional hardness and durability throughout the entire thickness of the plate. - SA400 Alloy Wear Plate (360/440 HB Through-Hardened)

Tough, dependable wear resistance for moderate abrasion service.

With SAS Global Premium Pyrite Hoppers, you get a tailor-made solution that protects your equipment, extends service life, and keeps your plant running efficiently.