PRESSURE FRAME WEAR PROTECTION

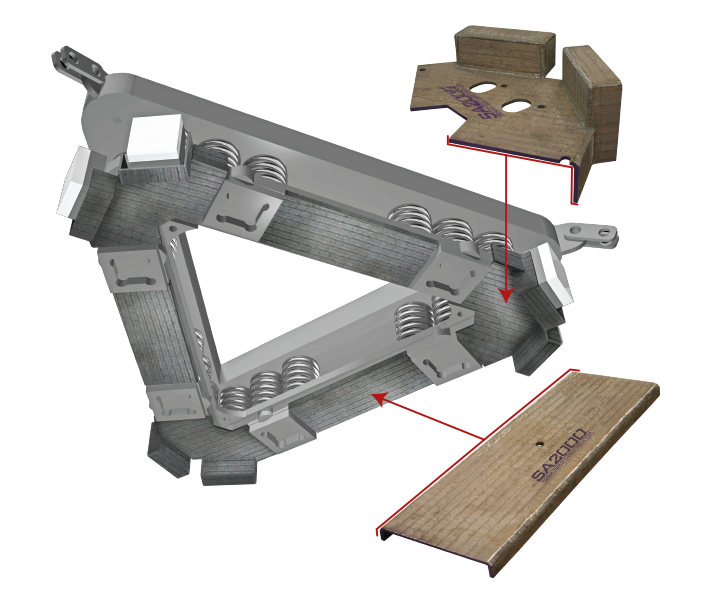

Pressure Frame Wear Plates & SAS Pressure Frame Protection System - MPS Series Mill Modernization

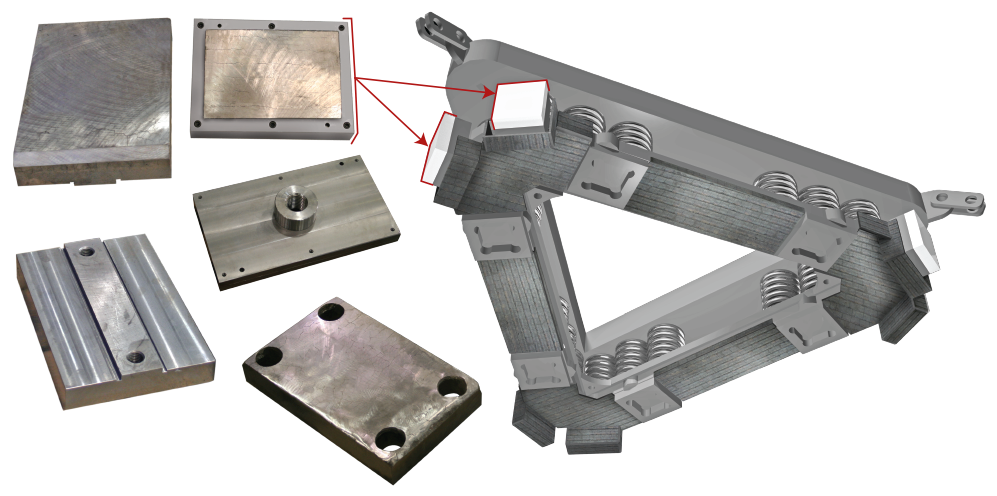

SAS Global Premium Pressure Frame Wear Plates: Engineered for Maximum Durability

SAS Global’s Premium Pressure Frame Wear Plates are custom-manufactured to match your specific operational requirements and service life goals. Built for extreme wear resistance, these plates provide critical protection for high-wear areas, reducing downtime and extending equipment life.

Abrasion-Resistant Material Options

SAS Global offers a range of premium wear-resistant materials, ensuring the best possible solution for your application:

- SA6000® Patented Microstructure Complex Carbide Overlay Plate

- SA2000® Premium Complex Carbide Overlay Plate

- SA1750CR® Premium Chromium Carbide Overlay Plate

- Vanguard Alloy Wear Plate

(460/540 HB Through-Hardened) - SA400 Alloy Wear Plate

(360/440 HB Through-Hardened)

SAS Pressure Frame Wear Protection System

The pressure frame in your MPS Pulverizer plays a critical role in directing pulverized coal toward the classifier—but it’s also exposed to constant erosion, leading to wear, inefficiency, and costly maintenance. Because replacing the pressure frame is a labor-intensive and time-consuming process, it’s essential to protect it with the best wear solution available.

Why Choose SAS Pressure Frame Wear Protection?

- Extends the service life of the pressure frame, reducing maintenance frequency.

- Minimizes erosion damage caused by pulverized coal flow.

- Reduces downtime by preserving structural integrity and reducing replacement needs.

- Engineered with premium wear-resistant materials for maximum performance.

With SAS Global’s advanced wear protection, you safeguard your pulverizer’s pressure frame—delivering longer service life, lower maintenance costs, and improved operational efficiency.