MINING HAUL TRUCK BED WEAR RESISTANT LINER SYSTEMS

Extended Service Life | Faster Unloading | Less Carryback | Reduced Hydraulic Wear

SAS Global's Performance Smooth Truck Bed Liner Systems are engineered to do more than just protect your haul truck beds—they are designed to optimize productivity, reduce maintenance, and deliver a measurable return on investment. Developed through advanced computer modeling and proven field testing, this liner package improves both wear resistance and structural performance under the harshest mining conditions.

Proven Performance Benefits:

- Engineered for a Completely Clean Dump – No more carryback; material is discharged cleanly and completely with every load.

- Faster Cycle Times – Material clears the bed by the time it reaches just 70% of full dump angle, reducing unloading time.

- Reduced Hydraulic System Wear – Less strain on hydraulics leads to lower maintenance and longer system life.

- Lightweight, High-Strength Design – Increases payload capacity while enhancing structural integrity.

- Quick Installation – Precision-fit components simplify the installation process, reducing labor and downtime.

- Easy to Maintain – Smooth surfaces resist material buildup, making cleaning and inspection simple.

Engineered for Mining Efficiency

SAS Global’s truck bed liner systems are crafted from premium wear-resistant materials, ensuring extended durability even in high-impact, high-abrasion environments. The system is customized to your fleet, maximizing performance while reducing carryback and operational delays.

Improve hauling efficiency and reduce wear with SAS Global’s Performance Smooth Truck Bed Liner Systems—delivering clean dumps, longer service life, and faster cycle times.

CAT 793D TAIL SECTION LINER: STILL GOING STRONG AFTER 10 YEARS IN SERVICE

65,000 Hours of Operation • Minimal Wear • Back in Service Without Replacement

At a large hard rock gold mining operation, a scheduled inspection of a CAT 793D haul truck revealed a powerful testament to the long-lasting performance of SAS Global’s Premium Liner Systems.

The truck had been running the same SAS SA1750CR Premium Chromium Carbide Overlay Plate liner system for over 10 years, enduring constant impact and abrasion in one of the most demanding mining environments.

Why It Matters:

- Unmatched Service Life: 10 years in service with minimal wear and zero replacements

- Field-Repairable: Hot spots were quickly addressed on-site, avoiding costly downtime

- Proven Return on Investment: Significant savings in liner replacement, labor, and maintenance

Inspection Results & Performance Highlights:

- The original SAS SA1750CR Tail Section was still intact after 65,000 operating hours

- Only minor hot spots were identified—easily corrected with field hardface welding

- Back 90” tail section liner was returned to production without replacement

- Thickness inspection showed only 0.187” of wear—just under half of the original thickness

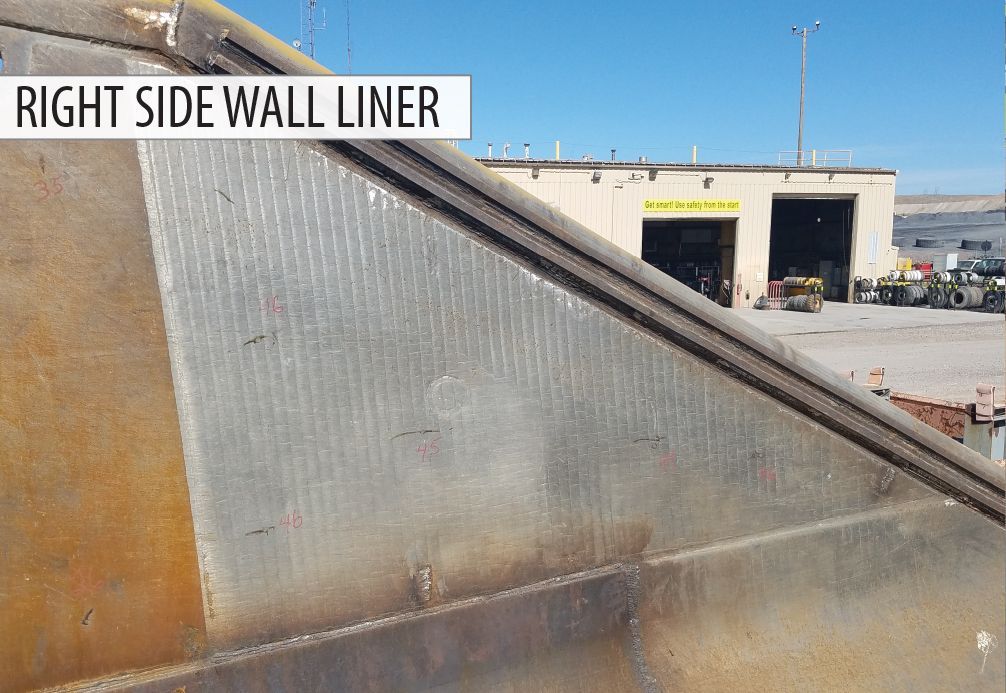

- Wall liners exhibited minimal signs of wear, further proving the system's durability

CAT 793D SAS PERFORMANCE LINER SYSTEM: EXPECTED TO LAST 4+ YEARS

SAS Liner System Outperforms Competitor in CAT 793D Truck Bed

- 1.5+ Years in Service

- Projected 4+ Year Lifespan

- 3X Longer Life Than Competitor Liners

Pictured is a SAS Global Premium Liner Package installed in a CAT 793D haul truck operating at a major gold mine in Nevada. This liner system has already been in continuous service for over 18 months, showing minimal signs of wear—with the mine expecting a total lifespan of 4 years or more.

In comparison, the previous competitor’s liners lasted only 16 months, requiring frequent changeouts and increased maintenance.

Performance Highlights:

- SAS Liner: 1.5+ years in operation with projected 4+ year service life

- Competitor Liner: Failed after only 16 months

- Significant reduction in downtime and maintenance costs

- Increased operational efficiency and haul truck availability