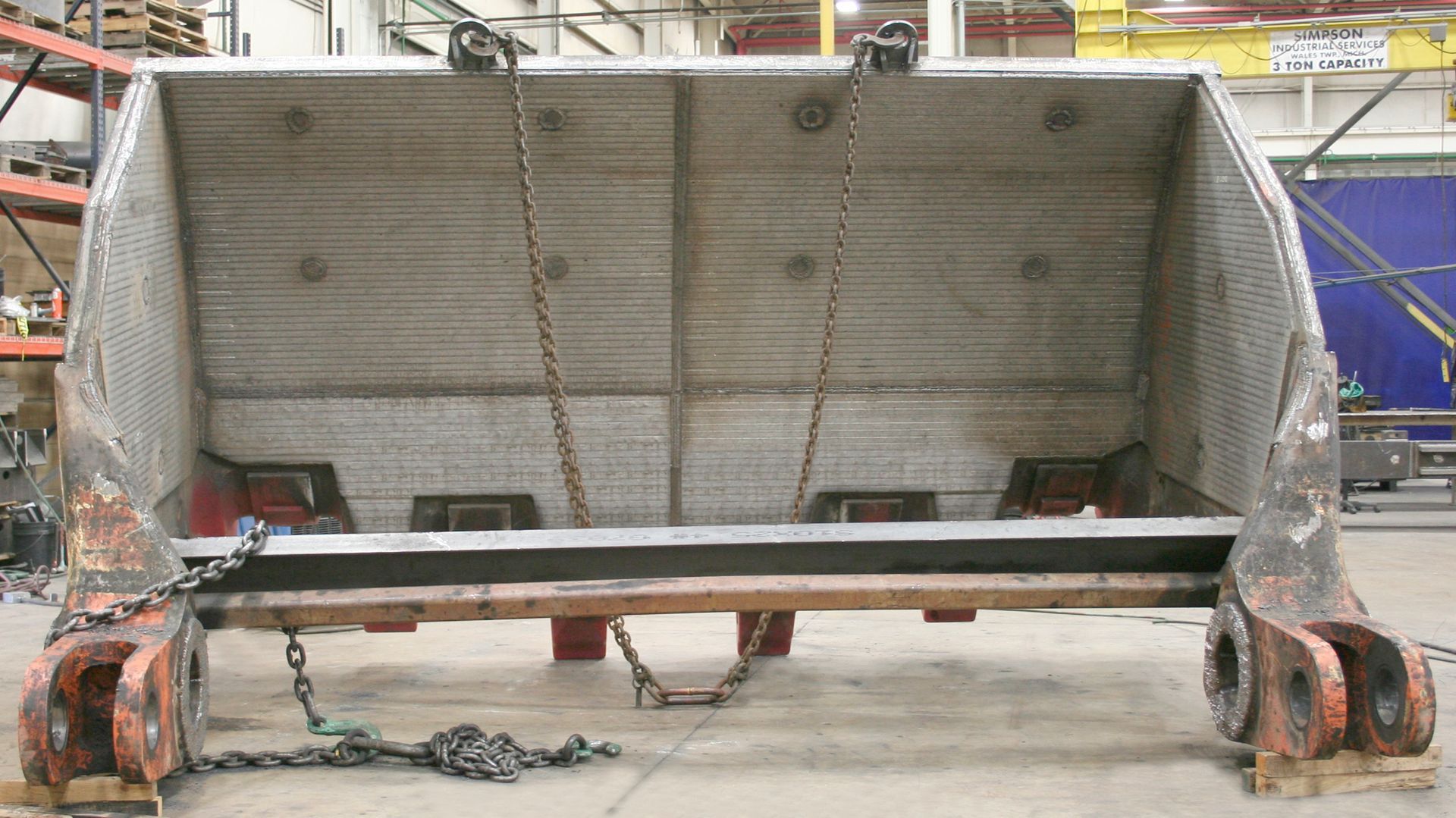

SHOVEL BUCKET LINER SYSTEMS & REBUILDS

Extended Service Life | Reduce Material Hang-Up | Faster Load & Unload

SAS Global designs and manufactures high-performance shovel bucket liner systems and rebuild solutions using SureAlloy® Premium Carbide Overlay Plate and Vanguard® Alloy Wear Plate. These advanced materials are engineered to provide superior abrasion resistance while significantly lowering the coefficient of friction—resulting in faster, cleaner loading and unloading cycles with reduced material buildup.

Whether you're rebuilding a worn bucket or outfitting a new one, SAS Global’s systems are custom-engineered to perform in the toughest mining environments.

Proven Performance Benefits:

- Increased Service Life: Premium SAS wear materials withstand extreme abrasion and impact, significantly outlasting conventional liners.

- Faster Loading & Unloading: The engineered low-friction surfaces allow material to flow in and out of the bucket with ease, shortening cycle times.

- Reduced Material Hang-Up: Smooth interior surfaces prevent carryback and sticking, maximizing payload efficiency.

Why Choose SAS Global Shovel Bucket Liners?

- Custom-designed for a wide range of shovel models

- Manufactured in the USA using field-proven wear materials

- Ideal for high-abrasion mining and excavation applications

- Available as complete liner packages or rebuild services

Boost your shovel performance and reduce downtime with SAS Global’s Performance Shovel Bucket Liner Systems—engineered for productivity, built for endurance.

SHOVEL BUCKET REBUILDS BY SAS GLOBAL