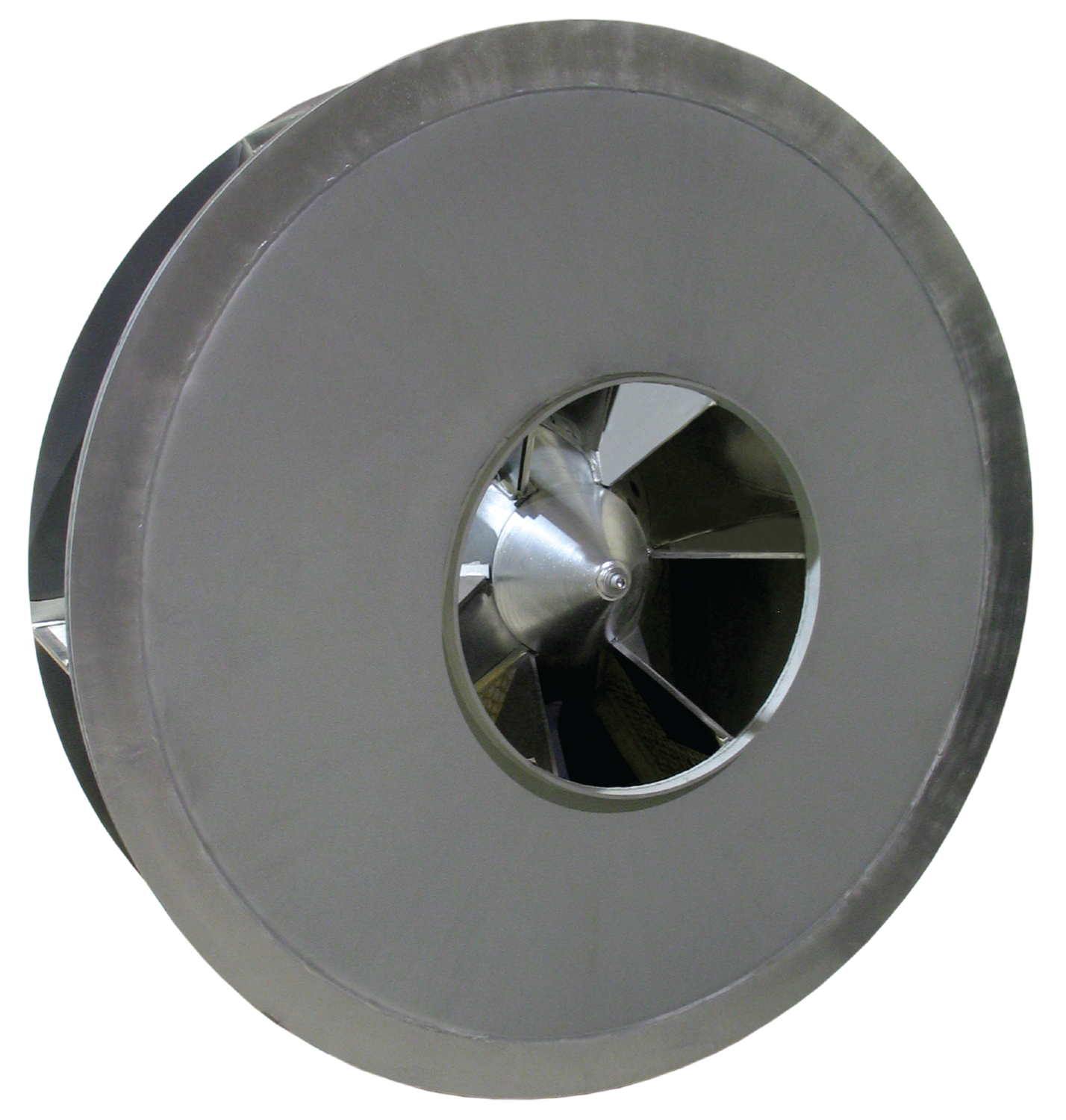

PATENTED SILVER BULLET EXHAUSTER FAN

Increase Air Flow | Eliminate Hub Failure | Designed for Extended Service Life

SAS Global Patented Silver Bullet Exhauster Fan: Engineered for Efficiency & Performance

The Patented Silver Bullet Exhauster Fan is designed to deliver maximum efficiency and increased airflow—without requiring costly modifications such as motor replacements, scroll liner changes, or structural upgrades.

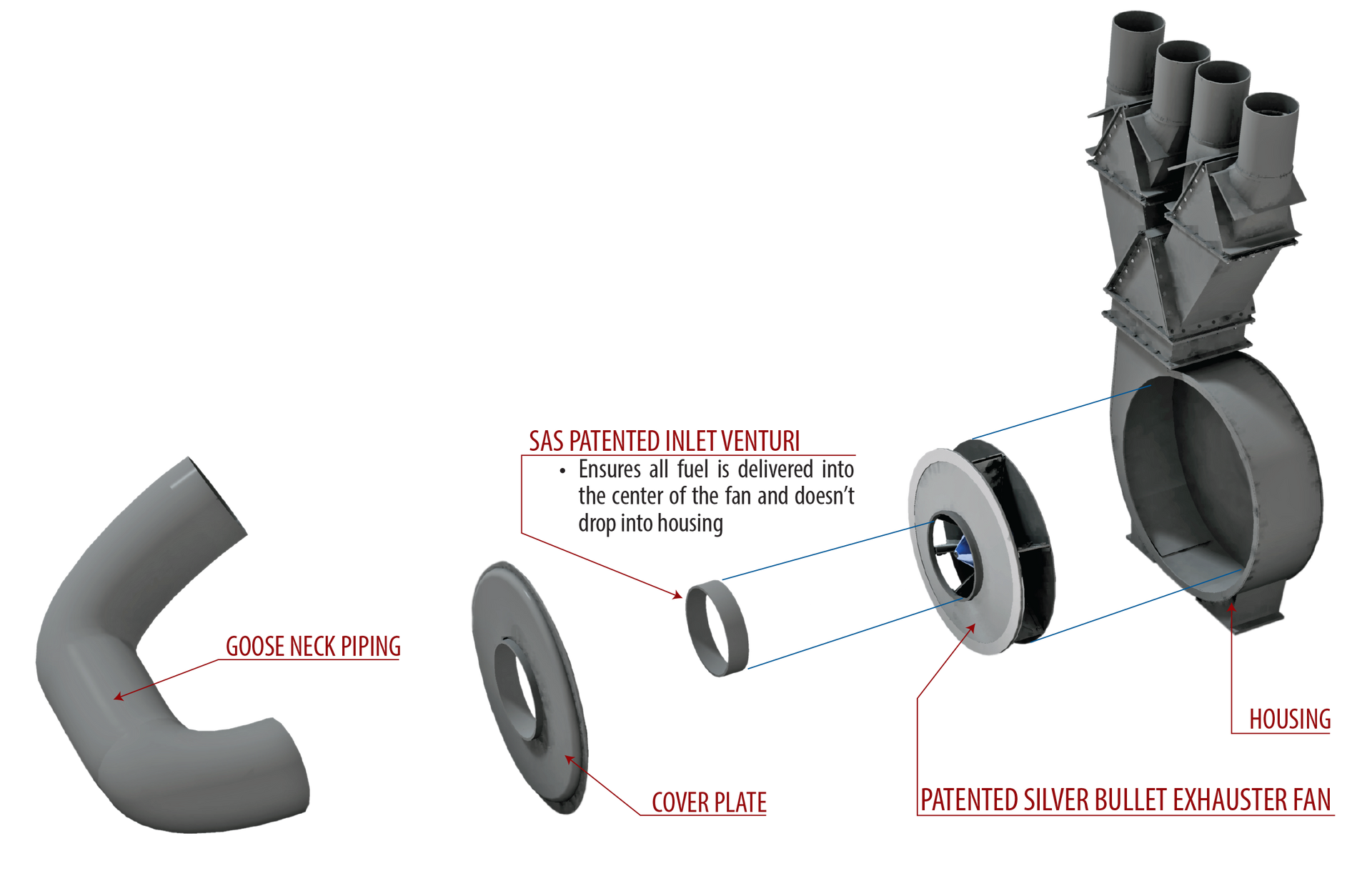

Unlike traditional designs, the Silver Bullet Exhauster Fan is custom-engineered to match the specific requirements of your plant. For example:

- If your system operates with a 55% efficient paddle wheel, SAS designs a fan that moves the same amount of air using less power—resulting in improved grinding capacity.

- If additional airflow is required for fuel drying or increased capacity, the Silver Bullet Fan is optimized to deliver the necessary air volume efficiently.

By factoring in grinding requirements, fuel characteristics, and plant operating conditions, SAS ensures that each Silver Bullet Exhauster Fan is built for peak performance and extended service life.

Key Features & Benefits

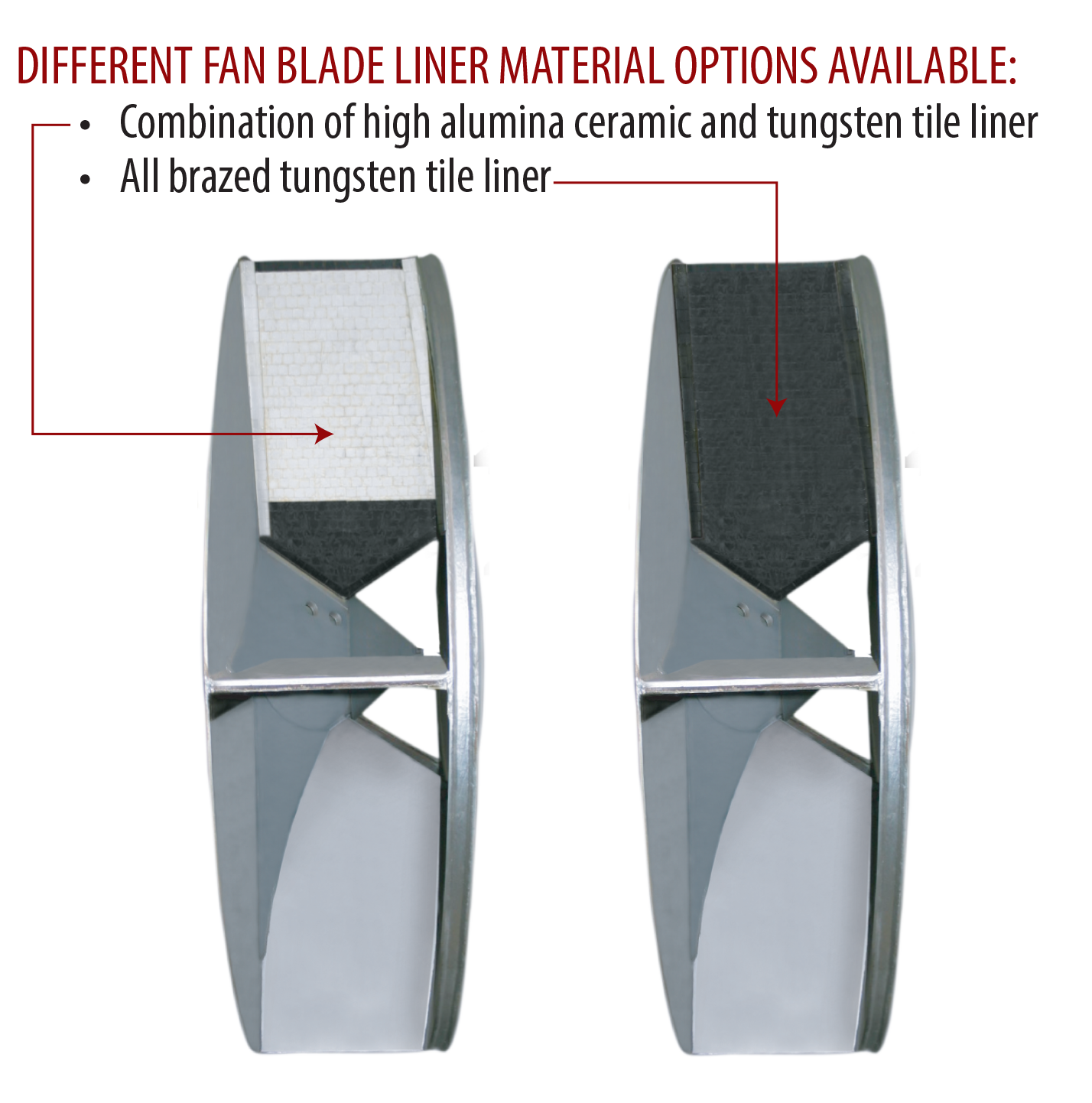

- Designed for maximum efficiency while maintaining ease of maintenance.

- Hub-centered design ensures balanced operation and minimizes stress.

- Engineered structure eliminates hub failure, reducing downtime and repair costs.

- Blade assembly is structurally attached to both the hub and back shroud for added durability.

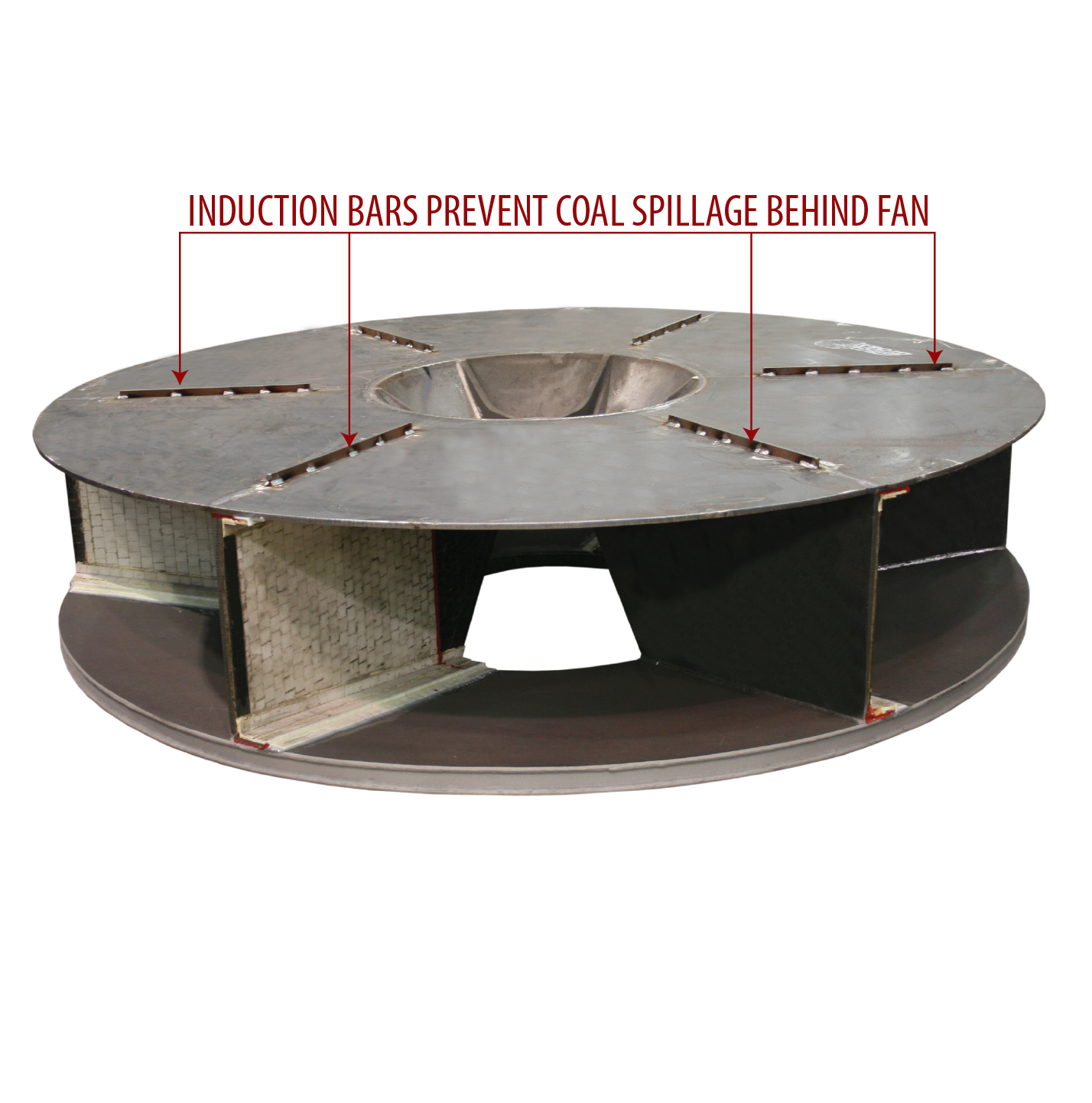

- Induction bars prevent coal spillage behind the fan, improving reliability.

- Patented SAS Inlet Venturi ensures full fuel delivery to the fan center, preventing material drop-out into the housing.

- Optimized airflow and energy efficiency, increasing overall mill performance.

- Stocking and maintenance programs available, ensuring you always have a spare fan ready when needed.