PATENTED IN-LINE DIFFUSER

Reduce NOx | Lower LOI | Reduce Slagging | Improve Combustion | Increase Burner Tip Life

Patented In-Line Diffuser: Optimized Fuel Flow for Improved Combustion Efficiency

The SAS Global Patented In-Line Diffuser is engineered to eliminate coal ribboning, ensuring a homogeneous air-fuel mixture for more stable combustion. By improving fuel distribution, the In-Line Diffuser helps reduce NOx emissions, lower LOI, minimize slagging, and extend burner tip life—enhancing overall boiler performance.

Key Benefits:

- Reduces NOx emissions by promoting complete and efficient combustion.

- Lowers LOI (Loss on Ignition) by ensuring a more uniform fuel distribution.

- Minimizes slagging by preventing uneven fuel flow and localized high-temperature zones.

- Extends burner tip life by reducing flame impingement and ensuring balanced combustion.

- Works with all burner types, enhancing fuel flow consistency across all designs.

How It Works

- Installed just after the last elbow or connection leading to the burner pipe.

- Eliminates coal ribboning, ensuring an even mixture of fuel and air reaches the boiler.

- Creates a uniform fuel flow pattern, allowing burners to operate more efficiently.

Every type of coal-fired burner benefits from the SAS Global In-Line Diffuser, as it optimizes combustion, reduces emissions, and extends component life.

WALL FIRED BURNER DIAGRAM: WITHOUT IN-LINE DIFFUSER

FLAME WITHOUT IN-LINE DIFFUSER

- Delayed combustion

- Poor mixing of primary air & coal

- Partial ignition

- Higher levels of LOI

- Higher levels of NOx

- Excessive nozzle wear

- Boiler slagging

WALL FIRED BURNER DIAGRAM: WITH IN-LINE DIFFUSER

FLAME WITH IN-LINE DIFFUSER

- Properly mixed fuel & air

- Proper & complete combustion

- Lower NOx

- Lower LOI

- Reduced nozzle wear

- Reduced boiler slagging

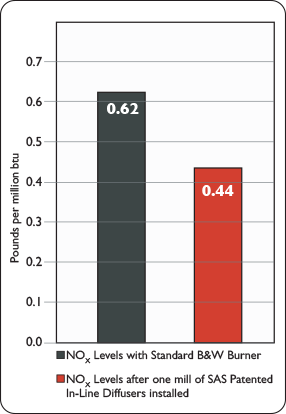

CASE HISTORY: DRAMATIC REDUCTION IN NOx LEVELS

A dramatic reduction in NOx emissions was recently achieved using the SAS Global Power Patented In-Line Diffuser, demonstrating its proven ability to optimize fuel-air mixing and enhance combustion efficiency.

Real-World Performance: 50% NOx Reduction

- SAS In-Line Diffusers were installed on one mill—accounting for one-third of a B&W Wall-Fired Boiler operating at full load.

- When the mill was brought back online, NOx levels dropped nearly 50%, from a baseline of 0.62 to 0.32.

- Due to operational adjustments, airflow was fine-tuned to stabilize NOx at 0.44, while also improving CO and O₂ levels.

Beyond NOx Reduction: Enhanced Flame Stability & Combustion Quality

- Utility engineers were amazed by the significant NOx reduction and the dramatically improved flame appearance.

- The success of the initial installation has led to the full-scale implementation of SAS Patented In-Line Diffusers across all remaining burners.

Proven Results, Immediate Impact

The SAS In-Line Diffuser provides measurable emissions reduction, improved fuel-air balance, and enhanced combustion stability, making it a cost-effective solution for cleaner, more efficient power generation.