PATENTED HIGH SPIN STATIC CLASSIFIER - REMOTE CLASSIFIER

Designed to Improve Fineness and Fineness Control of Your Remote Classifier

High Spin Static Classifier Retrofit: Precision Control & Proven Performance

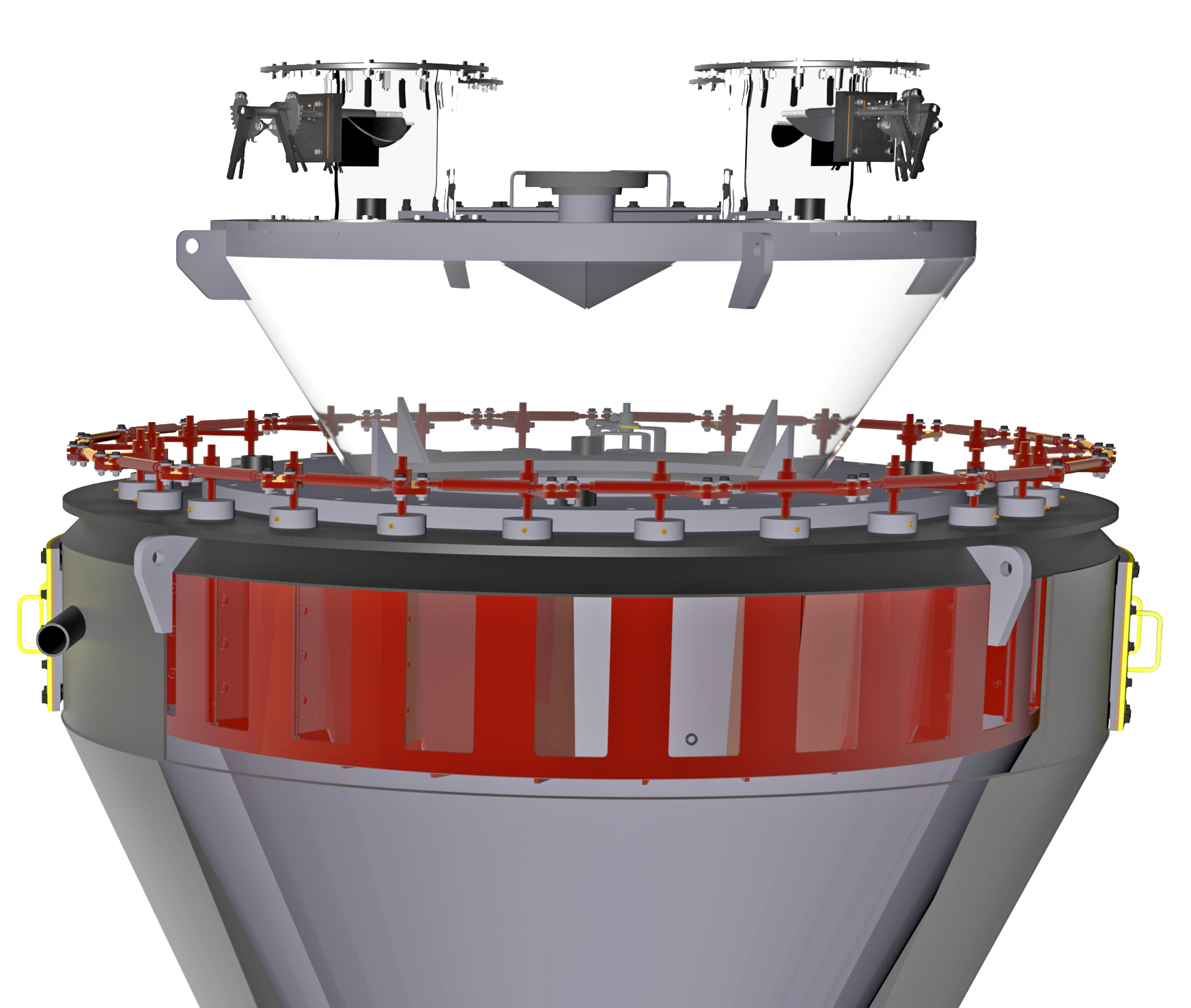

SAS Global’s Patented High Spin Static Classifier is an engineered retrofit designed to enhance the performance of most pulverizer designs and remote classifier systems. This advanced upgrade features externally adjustable blades, available with either:

- Dust-tight linkage system – Keeps blades free from coal build-up for long-term, maintenance-free operation.

- Individual blade adjustment points – Allows precise tuning per blade for optimized classification.

Seamless Adjustments, Manual or Automated

Blade positioning can be adjusted:

- Automatically via actuator for remote control.

- Manually with a single, easy-to-operate lever.

This flexibility gives operators real-time control over coal fineness to match changing load and fuel conditions.

High Performance Without High Capital Costs

The Adjustable High Spin Static Classifier Retrofit offers a cost-effective alternative to expensive Dynamic Classifier upgrades. Field-proven results from SAS customers show:

- 6% to 15% capacity improvements

- 99.8% passing 50 mesh

- 76.2% passing 200 mesh

- All achieved while grinding 42 HGI coal.

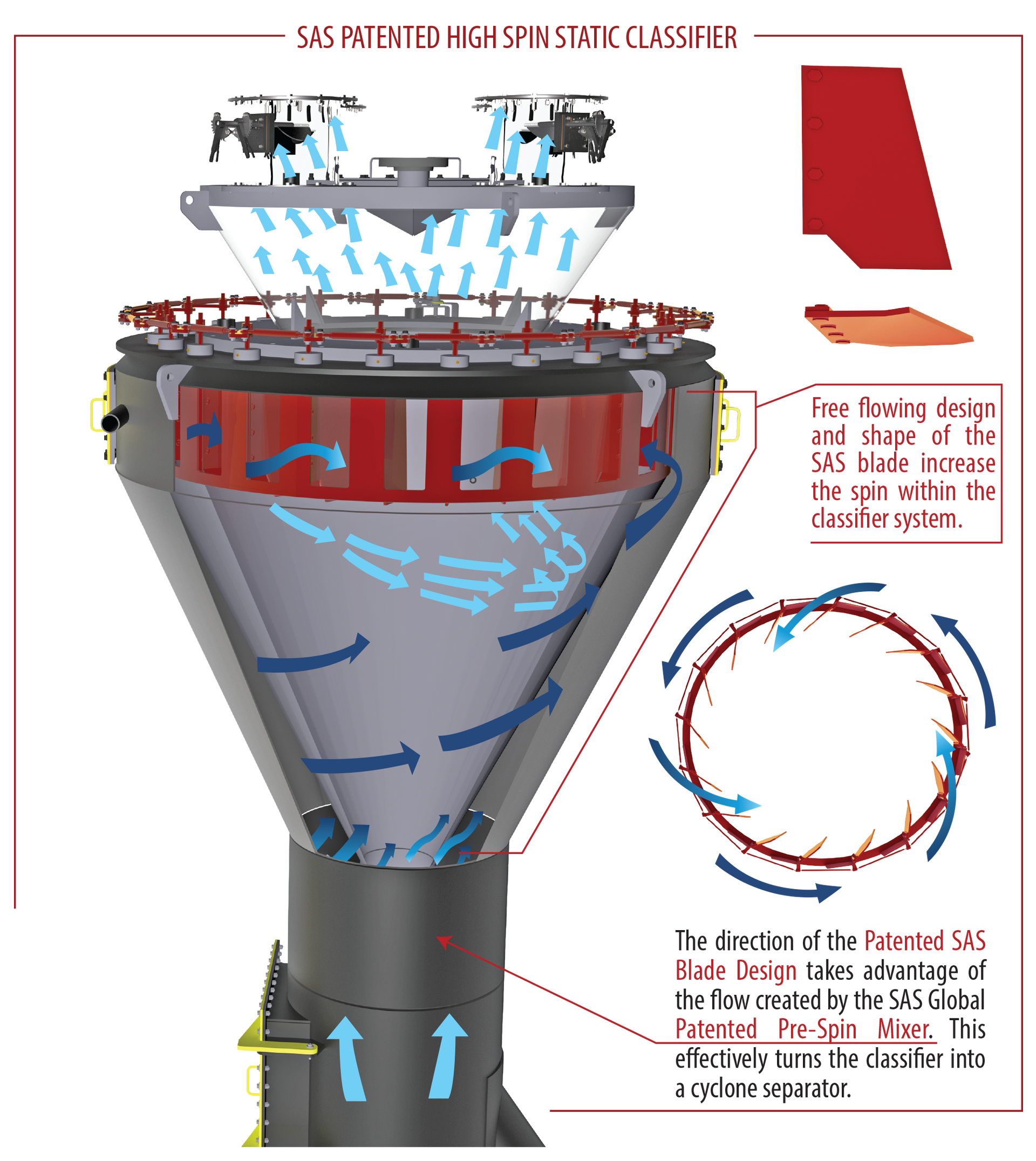

How It Works: Optimized Aerodynamics

The unique blade shape and downward extension are engineered to maximize the kinetic energy and rotational flow generated SAS Patented Pre-Spin Mixer. As circumferentially propelled coal particles enter the classifier, the flow is accelerated into the cone, creating a vacuum effect. This continuously increasing centrifugal acceleration effectively transforms the static classifier into a high-efficiency cyclone separator.

With SAS Global’s High Spin Static Classifier, you get precision control, improved capacity, enhanced fineness—and all without the capital cost of a full Dynamic Classifier retrofit.