GRINDING TABLE AND ROLLS/TIRES HARDFACING

Raw and Coal Mill Grinding Element Rebuild / Hardfacing

Cladtec Rebuild & Overlay Services: Extending the Life of Mill Grinding Components

Cladtec, a division of SAS Global Corporation, specializes in the rebuild and overlay of grinding tables, rolls, and tires for Raw Mills and Coal Mills across all major OEM designs. Our advanced hardfacing solutions deliver extended service life, reduced maintenance costs, and significant savings compared to full component replacements.

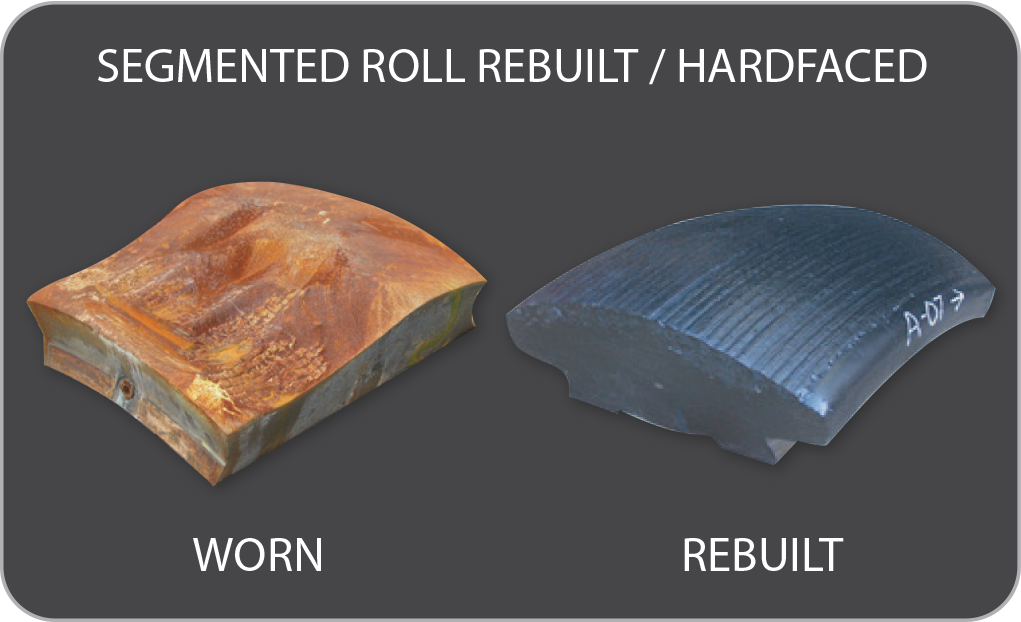

Grinding Rolls & Tires: A Smarter Approach to Maintenance

During typical maintenance outages, worn Ni-Hard tires are removed and replaced with expensive new parts from the OEM. Cladtec offers a smarter, more cost-effective alternative—rebuilding worn tires and rolls using our proprietary Chromium Carbide Hardfacing process.

The Advantage of Rebuilding with CT-28 Hardfacing

- Double the service life compared to new Ni-Hard tires

- Reduced material replacement in future maintenance cycles

- 50% lower costs on the second rebuild cycle

- Nearly 100% savings over two maintenance periods

What once was destined for the scrap yard becomes a long-term, cost-effective wear component—delivering high performance at a fraction of the cost.

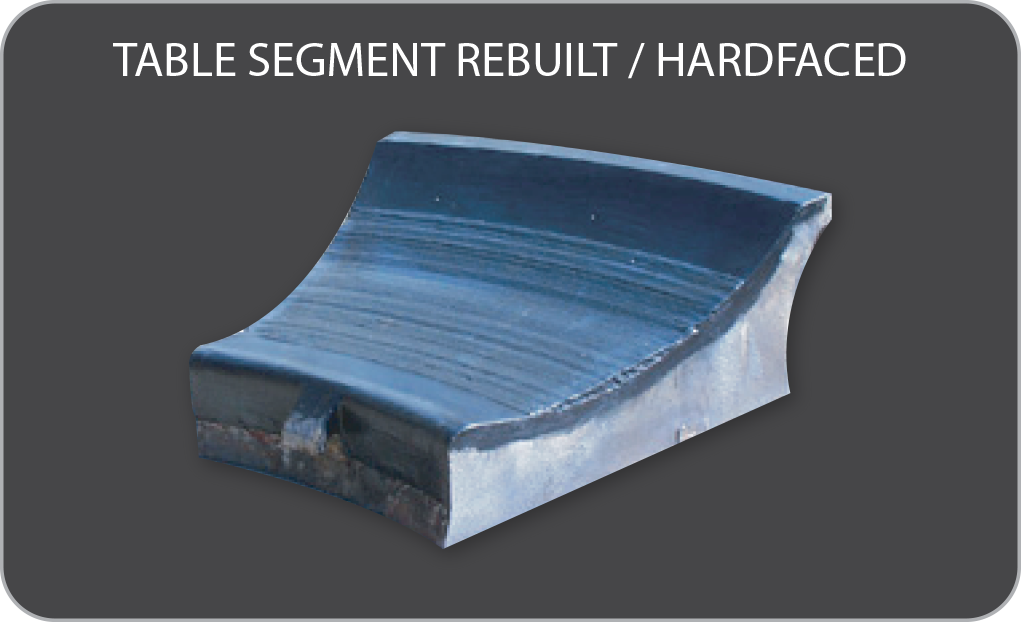

Grinding Tables: Repair Instead of Replace

Replacing worn grinding table segments can be costly and labor-intensive. Cladtec offers a more efficient solution—rebuild in place. Using automated overlay equipment, Cladtec repairs worn segments, fills severely eroded areas, and restores the table to its original profile—without removing the mill bottom.

Engineered for Performance: CT-28 Series Hardfacing

- Specially formulated wire with 28-32% Chromium and 5-6% Carbon

- Optimized carbide structure delivers twice the service life of OEM cast segments

- Restores performance and reliability at a fraction of replacement cost

With Cladtec’s advanced rebuild and overlay solutions, your mill components last longer, cost less to maintain, and keep your plant running efficiently.