SAS GRINDING PRESSURE MONITOR SYSTEM

Optimize Your MPS Pulverizer Performance in Real Time

Maintaining

proper grinding pressure in your

MPS Mill is

critical to ensuring

optimal capacity and fineness. Ideally,

grinding pressure should dynamically adjust with load—increasing as demand rises to maintain consistent performance.

Do you have

real-time visibility into your mill’s

actual grinding pressure? If not, the

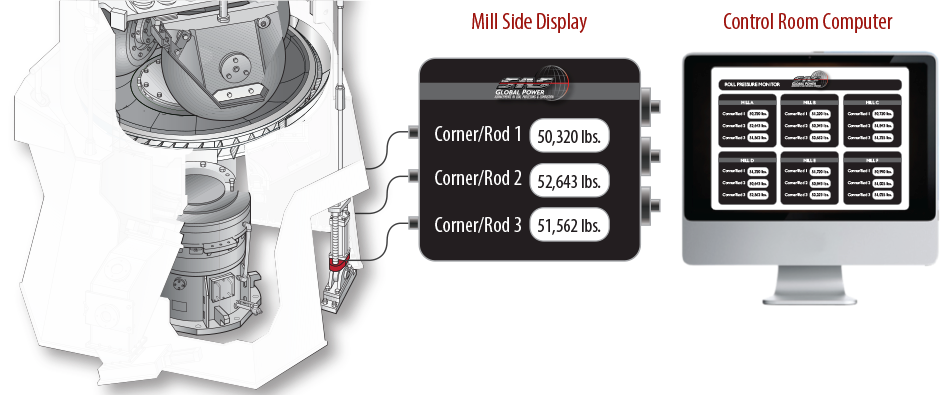

SAS Patented Grinding Pressure Monitor System provides

accurate, real-time data using

precision load cells to measure grinding pressure

at each grinding location within the vertical mill.

Key Benefits of Real-Time Grinding Pressure Monitoring

- Optimize & Monitor Capacity – Ensure your mill is operating at peak efficiency.

- Improve & Maintain Fineness – Control grinding pressure to achieve desired particle distribution.

- Calibrate Pressure for Load Control – Fine-tune fineness while managing mill differential pressure (DP).

- Monitor Grinding Surface Wear – Detect wear patterns early to schedule proactive maintenance.

- Identify Spring Degradation – Prevent capacity loss by detecting weakening grinding springs.

- Detect Tramp Iron in the Mill – Get real-time alerts to prevent damage and unplanned shutdowns.

- Balance Load on Main Bearings – Distribute forces evenly to extend equipment life.

With SAS Global’s Grinding Pressure Monitor System, you gain real-time insight and control—allowing you to optimize efficiency, extend component life, and maximize mill performance.

System Features:

- Real-time grinding pressure readings displayed locally or in the control room

- Load cell technology for precision measurement

- Improved control over mill performance, wear, and maintenance planning