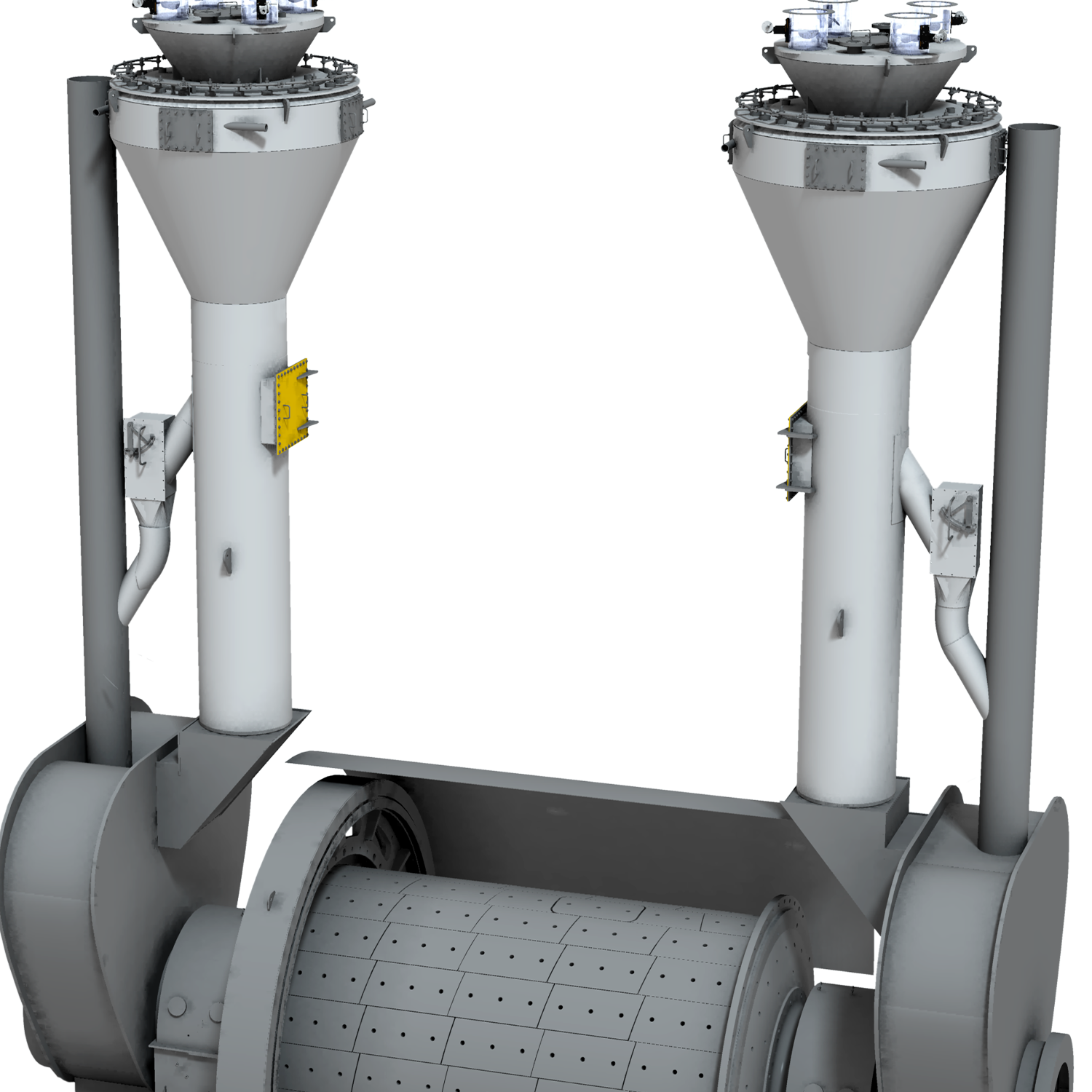

COAL MILL / PULVERIZER MODERNIZATION

Patented Mill Modernization Components | Complete Mill Inspection Services | Component Installation & Repair

Optimize Heat Rate with SAS Global Pulverizer / Mill Modernization & Turnkey Solutions

Unlock greater efficiency and fuel savings with SAS Global’s Pulverizer / Mill Modernization Programs—designed to increase capacity, improve fineness, balance fuel pipes, optimize air/fuel ratios, enhance combustion, and extend component life.

Why Mill / Pulverizer Performance Matters

The performance of your pulverizers directly impacts

boiler combustion efficiency.

Factors such as:

- Air/Fuel Ratio Balance

- Fineness Levels

- Coal Pipe Distribution

- Loss on Ignition (LOI)

All combine to determine how efficiently your fuel is burned. A modernized and properly tuned pulverizer directly improves heat rate, reducing fuel consumption and driving significant cost savings.

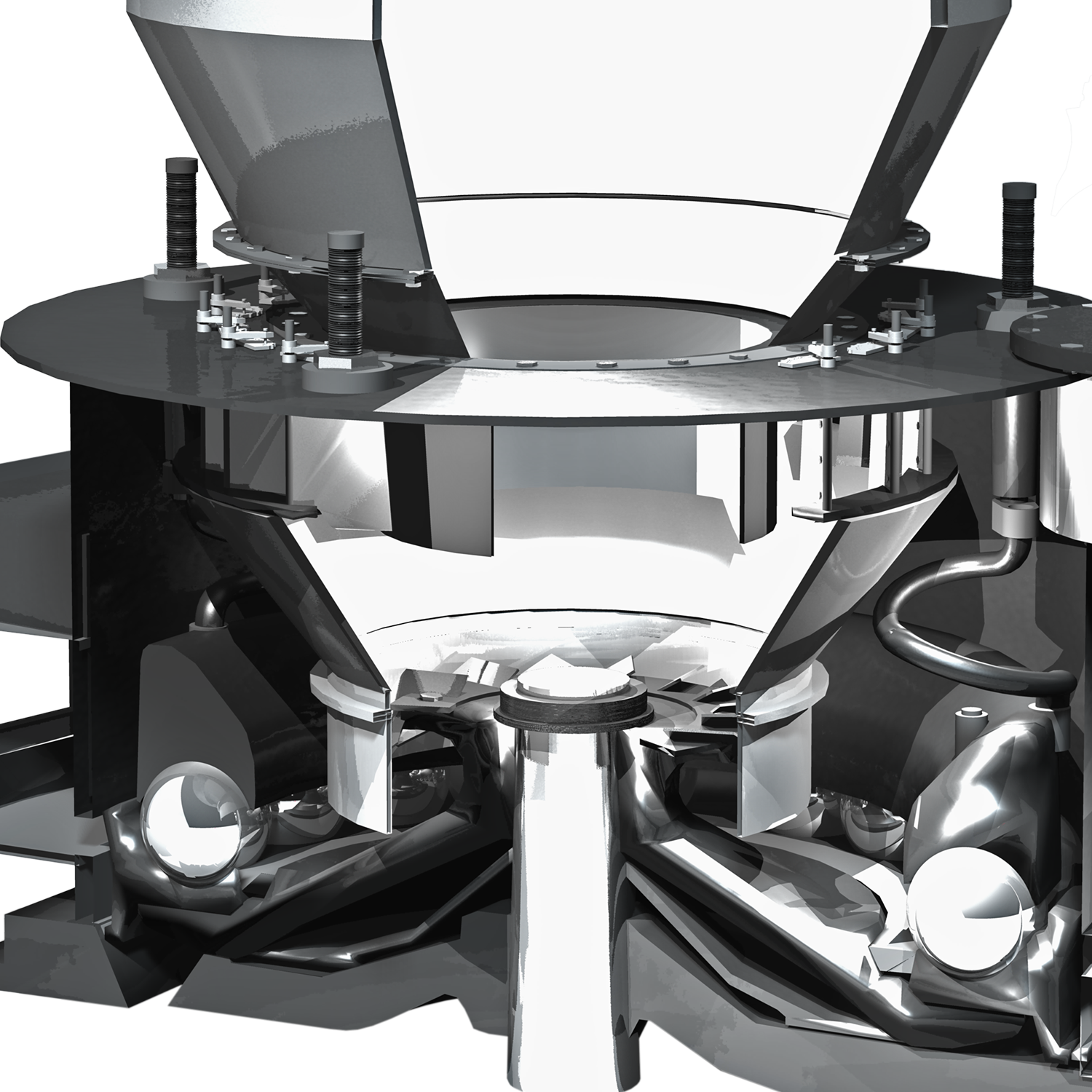

Custom-Engineered Modernization Components

SAS Global custom-engineers modernization components to match the exact operational parameters of your pulverizers. Whether you’re working with a legacy mill design or newer equipment, SAS delivers solutions tailored to your system and your goals.

Complete Turnkey Mill / Pulverizer Solutions

SAS Global offers end-to-end project management, including:

- Baseline Diagnostic Testing

- Engineering & Design

- Fabrication

- Installation

- Combustion Tuning

With SAS Global as your single-source partner, you gain both the technology and the expertise to optimize mill performance, improve heat rate, and save millions in fuel costs.

From diagnostics to installation and tuning—SAS Global delivers performance you can measure.

Explore a modernization component or service below by mill / pulverizer type

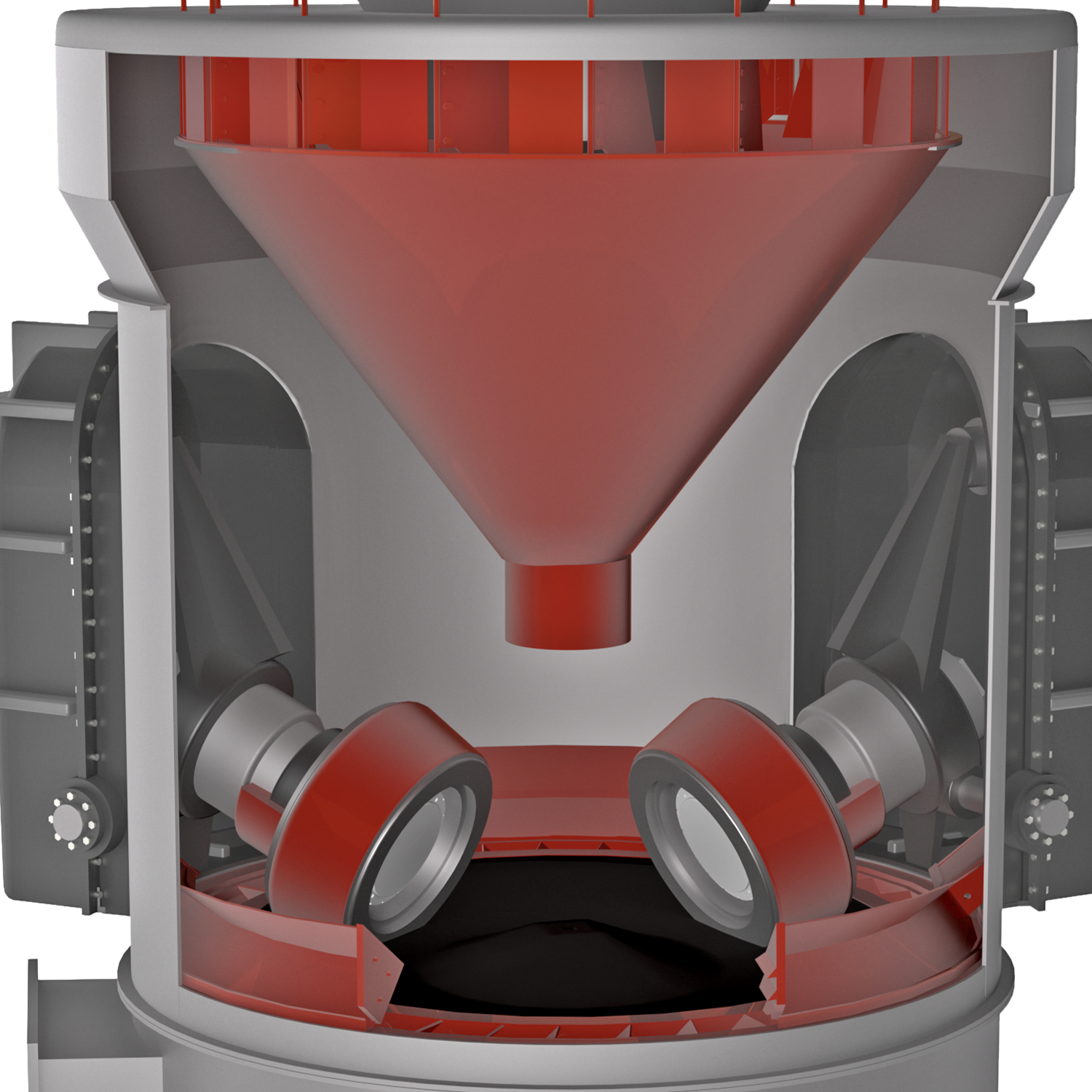

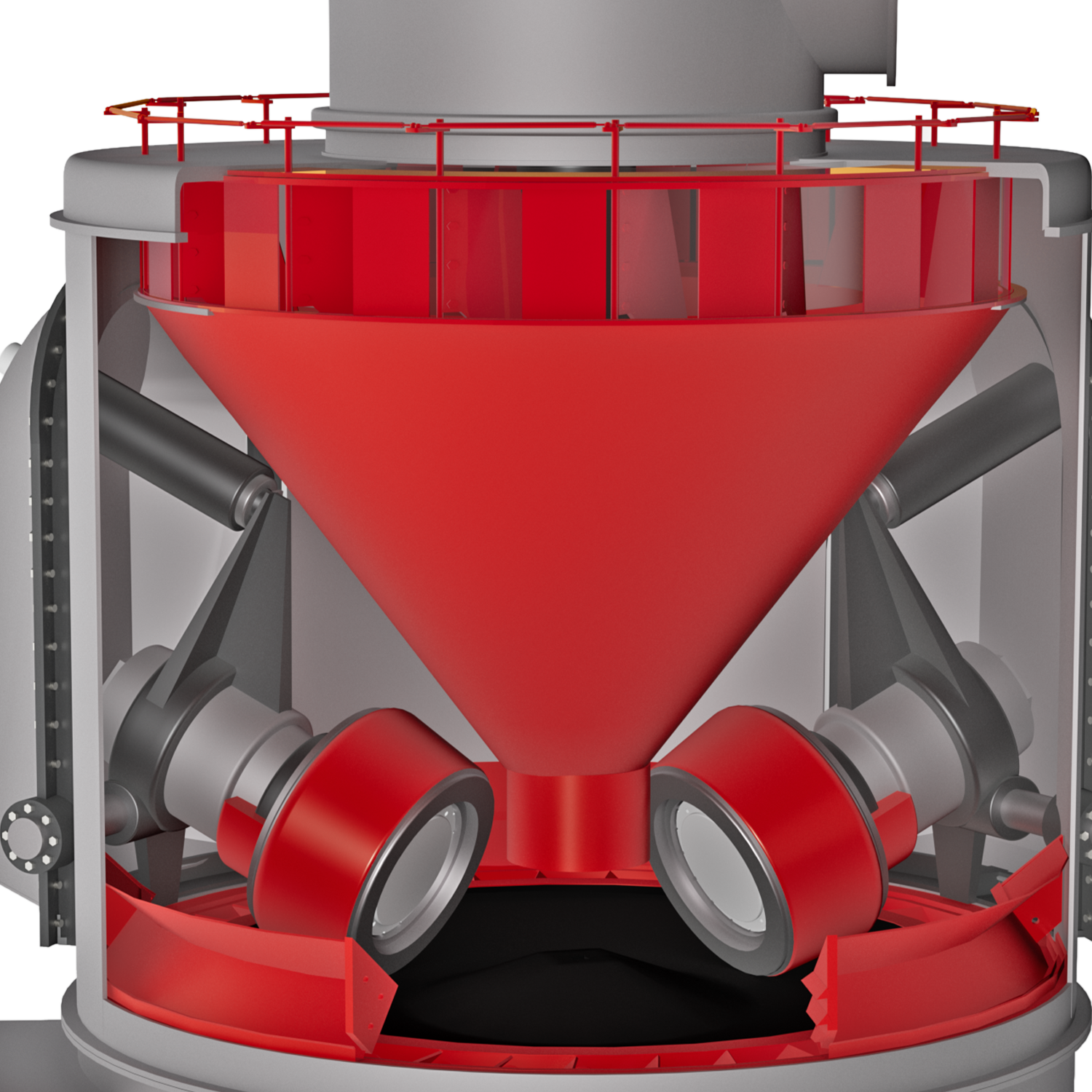

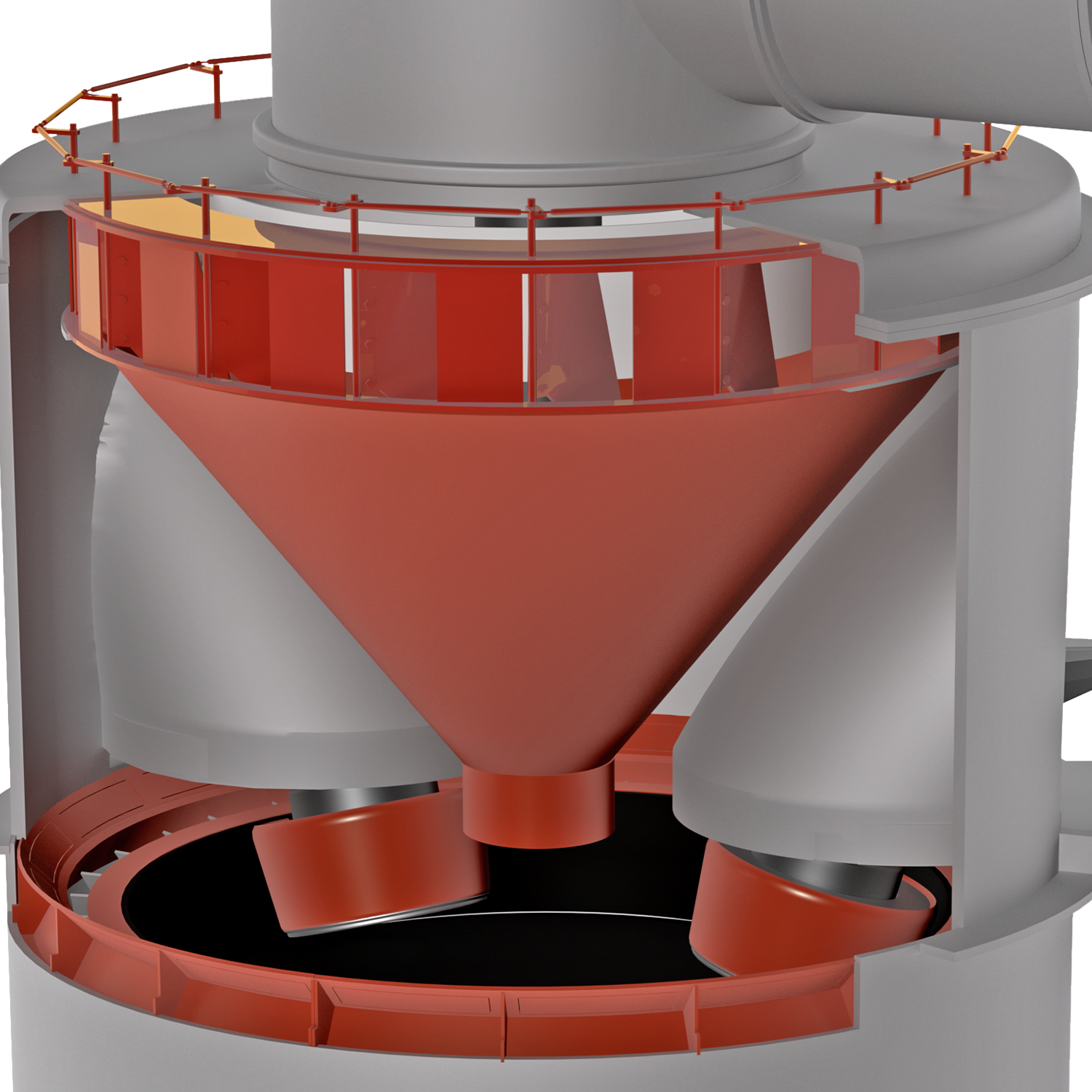

MPS SERIES

Mill Modernization Products & Services

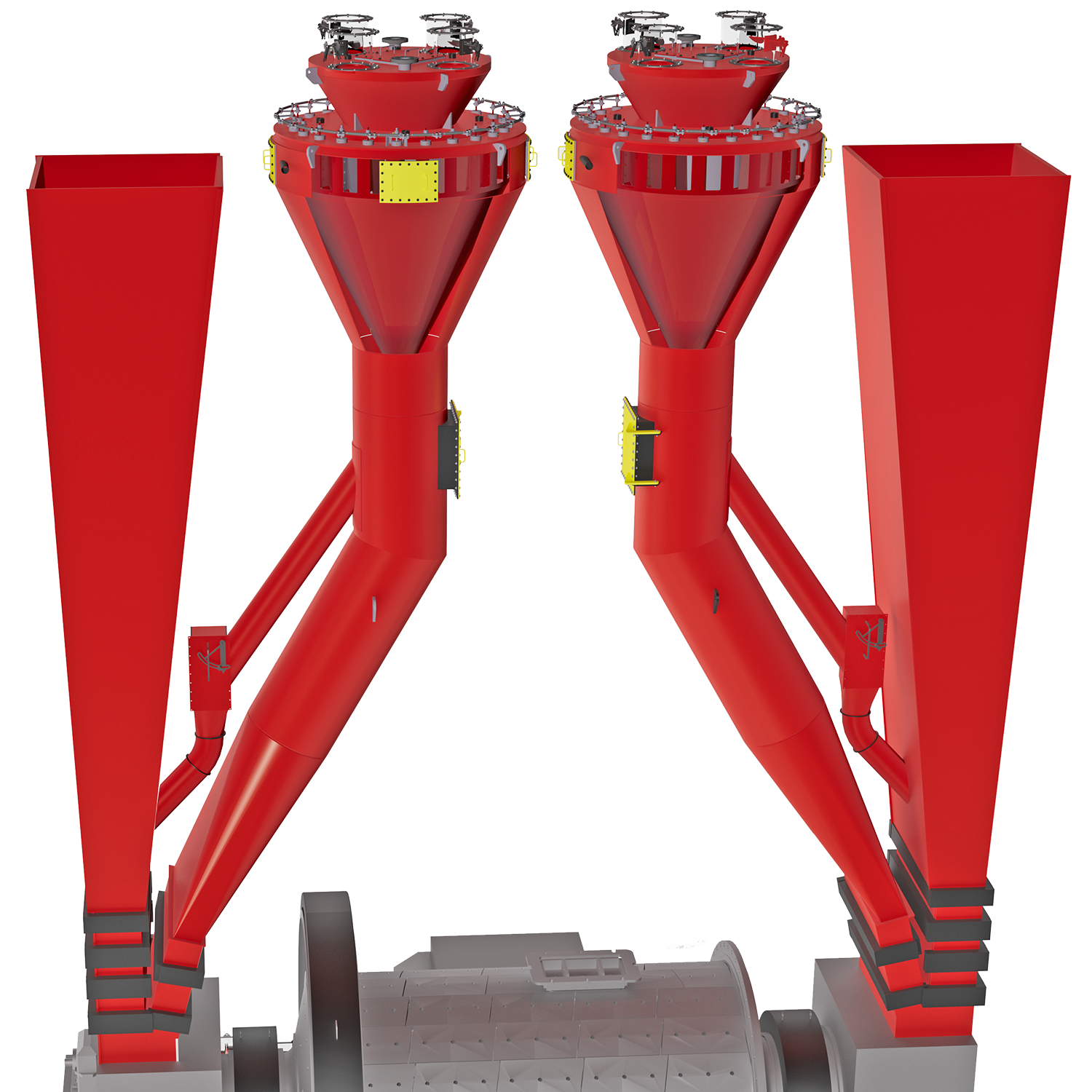

MBF SERIES

Mill Modernization Products & Services

CE HP SERIES

Mill Modernization Products & Services

CE RP SERIES

Mill Modernization Products & Services