WEAR RESISTANT LINERS - CHUTES & HOPPERS

Extended Service Life | Optimized Material Flow | Zero Hang-Up Operation

SAS Global’s Wear-Resistant Chute Liner Systems are purpose-built to handle the toughest material flow challenges in mining, power generation, and bulk material handling environments. Each system is custom-engineered to your specific application, ensuring optimal performance, improved material flow, and complete elimination of material hang-up.

With over 70 years of experience in wear-resistant technology, SAS Global delivers industry-leading durability through the use of advanced proprietary materials and flexible installation options.

Key Performance Advantages:

- Maximum Service Life – Built with premium wear-resistant materials designed to withstand extreme abrasion and impact.

- Improved Flow Efficiency – Engineered low-friction surfaces help eliminate buildup and improve throughput.

- Custom Fit & Easy Installation – Tailored to your chute dimensions and material conditions for plug-and-play performance.

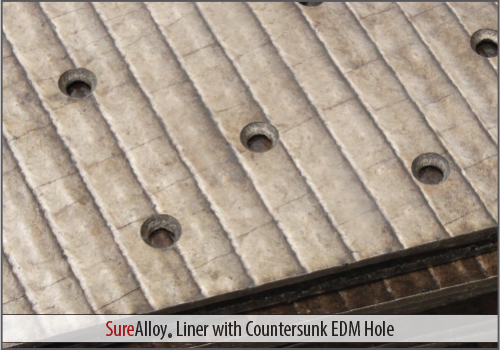

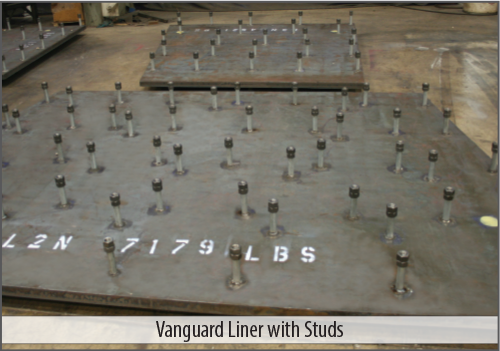

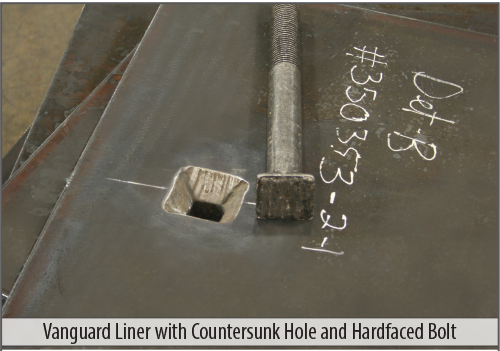

Attachment Options to Fit Any Application:

- Plug Weld

- Bolted

- Stud Mounted

- SAS QWA™ (Quick Wedge Attachment) System – For fast installation and easy maintenance

Key Premium SAS Global Material Options Include:

- SA6000® – Patented Microstructure Complex Carbide Overlay Plate for extreme wear and impact environments

- SA2000® – Premium Complex Carbide Overlay with enhanced toughness and wear resistance

- SA1750CR® – Industry-proven Chromium Carbide Overlay for high-abrasion applications

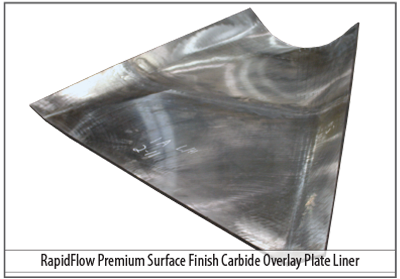

- RAPIDFLOW® – Smooth Surface Finish Carbide Overlay for improved material flow and reduced carryback

- Vanguard® Wear Plate (460/540 HB) – Through-hardened alloy for high impact and abrasion resistance

- SA400 Wear Plate (360/440 HB) – A tough, versatile wear plate suitable for moderate to heavy wear conditions

When maximum liner life and material flow matter, trust SAS Global’s Chute Liner Systems—engineered for performance, built to last.