CHUTES & HOPPERS - WEAR RESISTANT LINERS

Extended Service Life | Optimized Material Flow | Zero Hang-Up Operation

SAS Global designs and fabricates high-performance chutes, hoppers, and liner systems to withstand the harshest material handling environments. With over 70 years of expertise in wear-resistant technology, SAS engineers each solution to provide exceptional durability, superior flow performance, and complete elimination of material hang-up.

These systems are built using proprietary premium-grade materials, delivering industry-leading longevity and consistent operational efficiency—from ore transfer points to processing equipment.

Key Benefits:

- Maximized Service Life – Built from advanced alloys and overlays that resist impact and abrasion.

- Improved Flow Efficiency – Low-friction surfaces ensure smooth material movement, reducing buildup and blockages.

- Custom-Engineered for Your Operation – Precision fit and optimized design based on your specific flow, size, and material requirements.

- Reduced Maintenance and Downtime – Longer wear life leads to fewer changeouts and lower operational costs.

Premium SAS Global Material Options Include:

- SA6000® – Patented Microstructure Complex Carbide Overlay Plate for extreme wear and impact conditions.

- SA2000® – Premium Complex Carbide Overlay Plate designed for superior wear life and toughness.

- SA1750CR® – Premium Chromium Carbide Overlay Plate proven in high-abrasion applications.

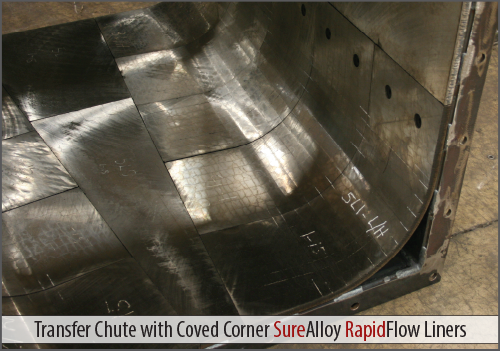

- RapidFlow® - Premium Smooth Surface Carbide Overlay Plate for improved material flow.

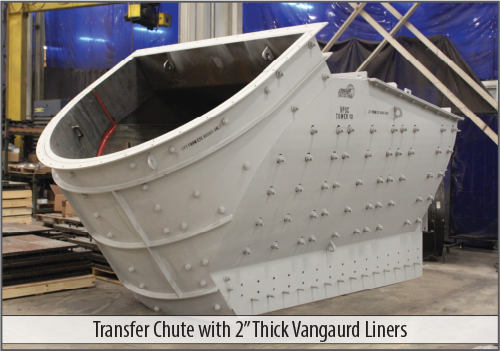

- Vanguard® Premium Alloy Wear Plate (460/540 HB) – Through-hardened for consistent hardness throughout the plate.

Whether you're upgrading a single hopper or overhauling your entire material handling system, SAS Global delivers chute and liner systems that perform longer, flow better, and cost less to maintain.