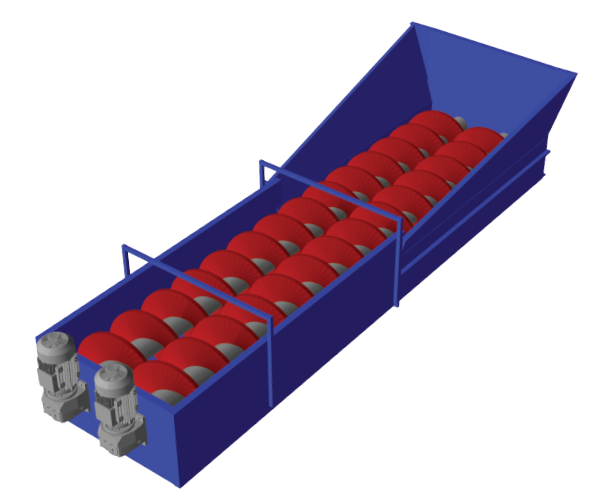

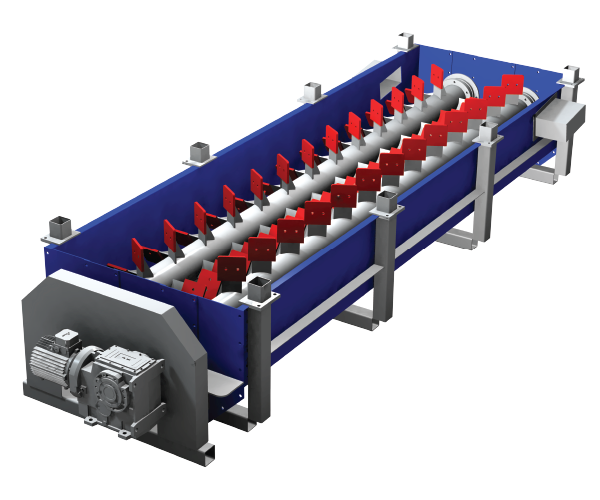

LOG & SCREW WASHER WEAR RESISTANT COMPONENTS

Built to Extend Service Life | Reduce Downtime | Boost Throughput

Your log and screw washers take a beating—and SAS Global builds the components that can take it. From abrasion-resistant liners to premium paddles and augers, our wear solutions are engineered to outlast OEM parts, keep material moving, and minimize unplanned shutdowns.

With over 70 years of wear technology experience, we not only fabricate parts, we engineer the materials that make them better. Whether you're fighting sand, aggregate, or other abrasive materials, SAS components are custom-built for performance.

Engineered Solutions Include:

- Wear-Resistant Troughs: Built from SAS premium plates for high-abrasion environments

- Paddles: Fabricated for superior wear and strength under continuous load

- Augers & Hardfacing: Reinforced with SAS hardfacing to extend screw life and improve efficiency

- Abrasion-Resistant Liners: Custom-fit protection for trough interiors and critical wear areas

Your Benefits:

- Reduce frequent changeouts and lower maintenance costs

- Improve production consistency with fewer interruptions

- Get custom-fit, ready-to-install components for your specific equipment

From liners to augers, SAS Global gives your washer the toughness it needs to stay productive longer.

Available SAS Global Wear Material Options:

- SA6000®: Patented microstructure complex carbide overlay plate for extreme wear zones

- SA2000®: High-performance complex carbide overlay for enhanced toughness

- SA1750CR®: Industry-trusted chromium carbide overlay for extended abrasion resistance

- Vanguard® Wear Plate (460/540 HB): Through-hardened plate designed for high impact

- SA400® Wear Plate (360/440 HB): A versatile solution for heavy-duty applications