ENGINEERED FOR MAXIMUM WEAR RESISTANCE & DURABILITY

Premium Complex Carbide Overlay Plate

Tired of excessive downtime and costly replacements? SA2000 is a high-performance alloy designed with a refined microstructure that outlasts conventional chromium carbide alloys in the toughest industrial environments.

Why Choose SA2000?

Our advanced metallurgy features a dense network of ultra-hard primary carbides, delivering unmatched wear resistance and durability. Here’s how it outperforms standard wear plates:

- Superior Wear Resistance – Reduced carbide spacing increases toughness, minimizing material degradation

- Enhanced Impact Strength – A high density of smaller carbides absorbs shock and prevents cracking.

- Extreme Temperature & Corrosion Resistance – Inert refractory carbides protect against heat and harsh conditions.

- Proven Performance in Demanding Applications

Cut Costs & Boost Efficiency

By upgrading to SA2000, you can:

- Increase Production – Less downtime, more throughput.

- Reduce Maintenance & Labor Costs – Fewer replacements mean lower expenses

- Minimize Downtime – Keep operations running longer with less interruption.

Built for engineers. Trusted by maintenance teams.

Upgrade to SA2000 and experience the

difference in performance & reliability.

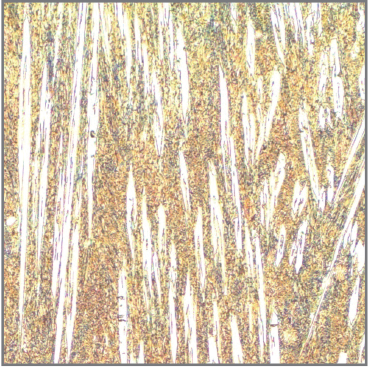

Standard Chromium Carbide Microstructure at 100X

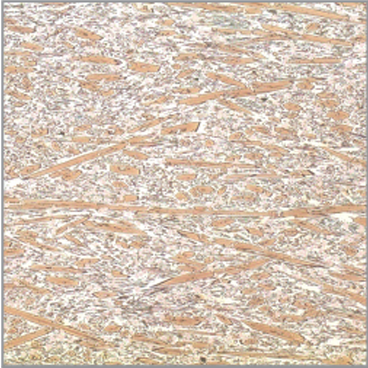

SA2000 Microstructure at 100X: Refined, Dense, Microstructure with smaller carbides

Experience Unmatched Durability & Performance with Our Cutting-Edge Carbide Technology!

Harness the power of our refined microstructure, engineered with advanced complex carbides that set a new standard in longevity and resilience.

- Enhanced Wear Resistance & Toughness: Our optimized carbide spacing delivers remarkable strength, keeping your equipment running longer.

- Unrivaled Impact Resistance: A high density of finely distributed carbides means your machinery can take on even the toughest challenges.

- Extreme Temperature & Corrosion Resilience: Inert refractory carbides boost performance under heat and harsh environments, ensuring reliable operation.

- Minimal Carry Back & Sticking: Enjoy smoother operations with significantly reduced material build-up.

Upgrade to SA2000 and transform your equipment—from bins and hoppers to deflector screens, excavator buckets, truck dump trays, and chute liners.

Experience up to double the service life compared to traditional chromium carbide overlay plates and drive your productivity to new heights!

Feed Chute Case Study: SA2000 Delivers 2X the Wear Life

Discover how SA2000® Premium Complex Carbide Overlay Plate transforms performance in demanding environments. Installed in the high-impact zones of a 3500 TPH coal load chute, SA2000 tackles a robust 70/30 blend of Powder River Basin and Eastern Bituminous coal (50/45 HGI), where previous chromium carbide overlays struggled to keep up—lasting only 3 to 6 months.

After 9 months in service, inspections reveal that the SA2000 liners show little to no wear, demonstrating extraordinary durability and resilience. The dramatic difference is clear: while traditional materials falter, SA2000 continues to protect your equipment, delivering up to 1.5 to 2 times the service life.

In contrast, you can also observe the failure of ceramic tiles breaking away from the old impact areas.

Upgrade to SA2000 and experience a new era of wear resistance that keeps your operations running smoother, longer, and with far less downtime!

Available SA2000 Thickness Combinations