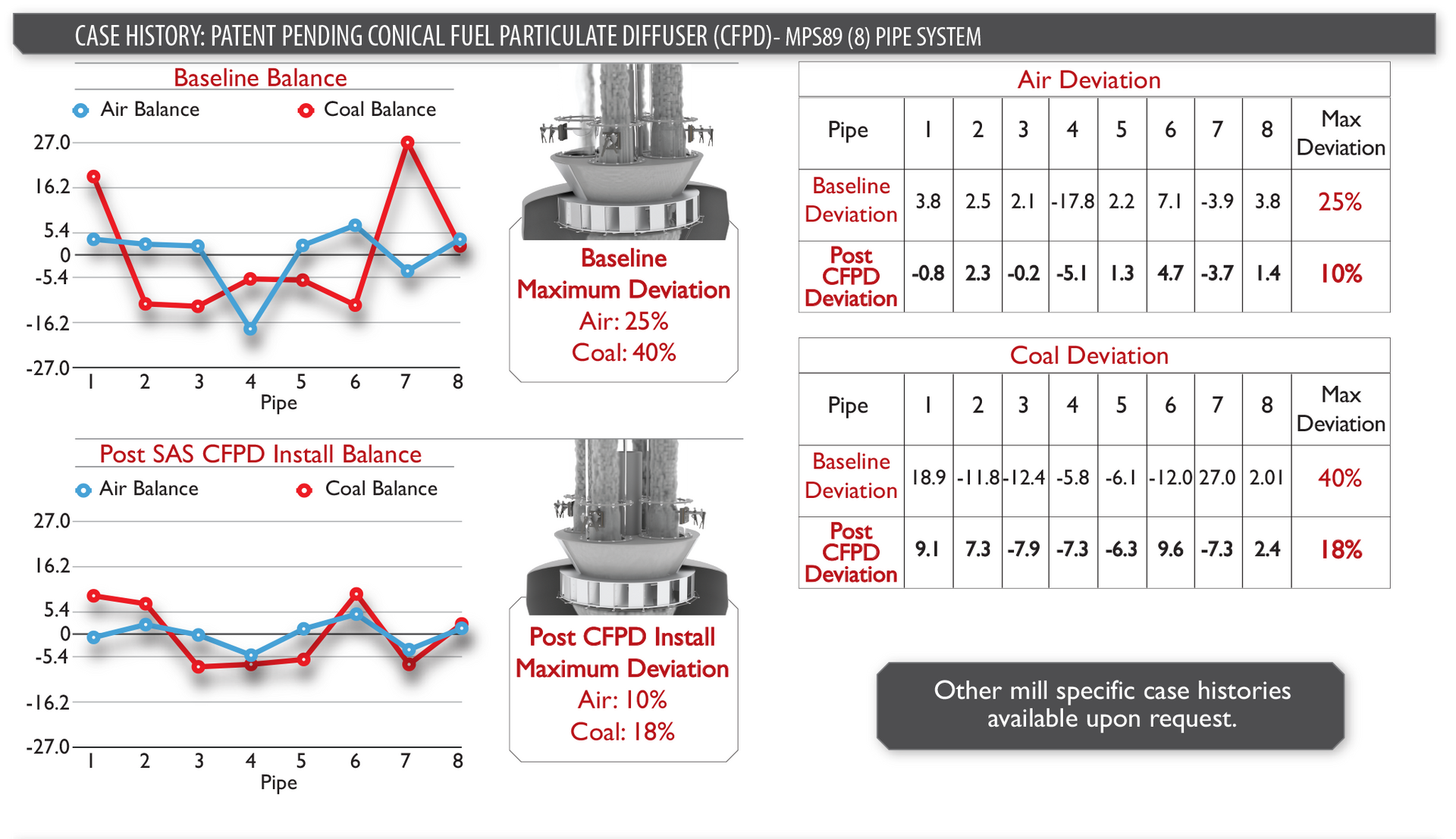

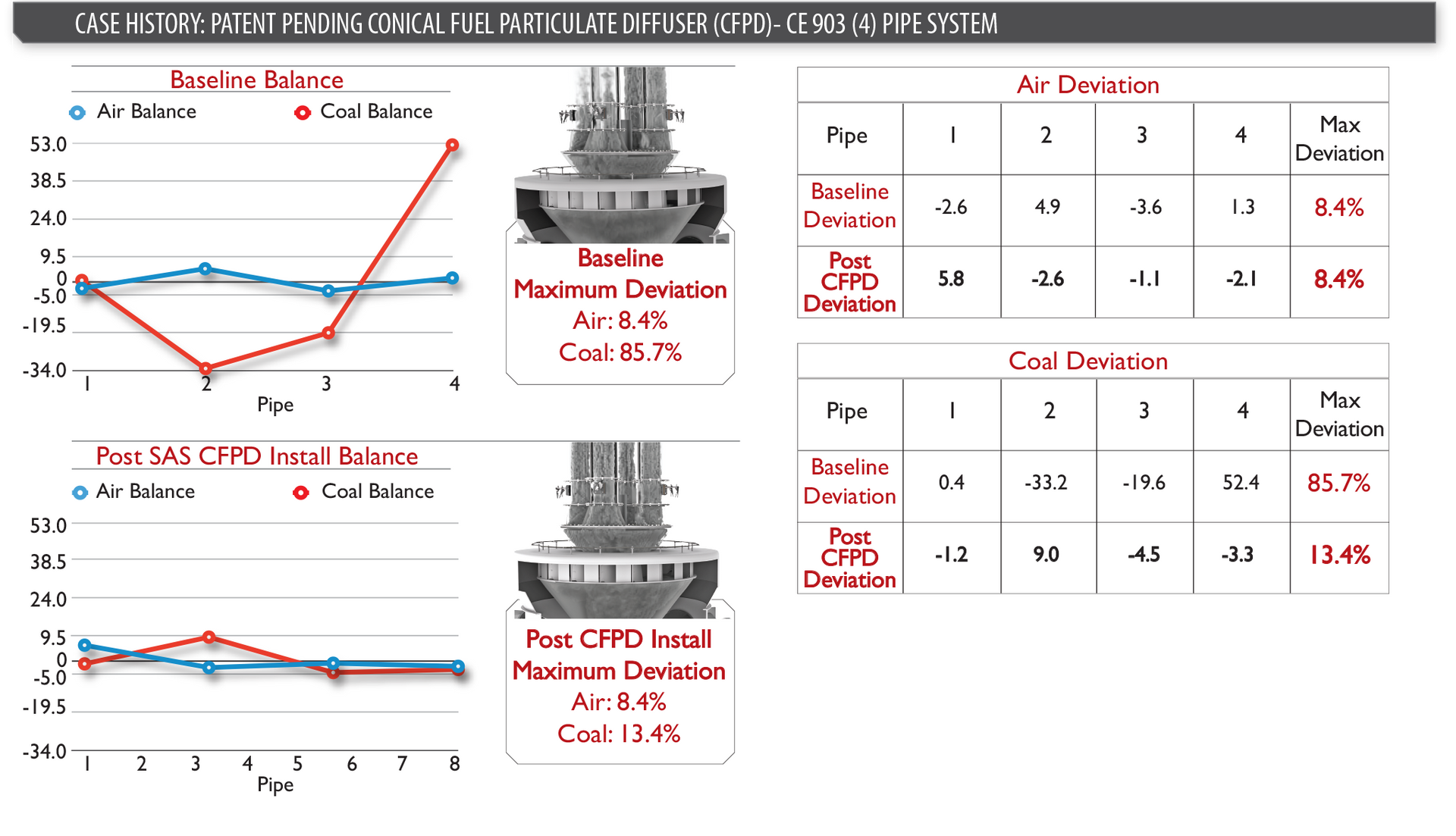

CONICAL FUEL PARTICULATE DIFFUSER

Balance Fuel Flows | Improve Air-Fuel Ratios | Improve Combustion | Reduce Emissions

SAS Global Conical Fuel Particulate Diffuser: The Proven Solution for Fuel Pipe Balancing

Through extensive modeling, field research, and real-world testing, SAS Global has identified that fuel pipe imbalance must be addressed at the source—as coal exits the pulverizer. Simply adjusting downstream components is not enough. That’s why SAS developed the Conical Fuel Particulate Diffuser, a patented system that optimizes fuel distribution immediately upon exiting the mill, creating a homogeneous air-fuel mixture for superior combustion efficiency.

How the SAS Conical Fuel Particulate Diffuser Works

- Ensures uniform mixing of pulverized coal and air as it exits the upper turret.

- Distributes fuel evenly across all outlet pipes, eliminating imbalances.

- Allows for precise orificing (if needed) to match fuel pipe velocities.

- Reduces NOx, LOI, and unburned carbon, improving boiler efficiency.

Compatible with All Major Pressurized Mill Designs

The SAS Conical Fuel Particulate Diffuser is designed to integrate seamlessly with all types of pressurized mills that use outlet chambers, including:

- MPS Pulverizers

- CE Mills

- MBF Pulverizers

- IHI Mills

- Riley Ball Mill Remote Classifiers

- FW Ball Mill Remote Classifiers

By ensuring proper air-to-fuel ratios across all burner pipes, the SAS Conical Fuel Particulate Diffuser enhances combustion stability, reduces emissions, and improves heat rate — delivering a cost-effective, performance-driven solution for modern power plants.

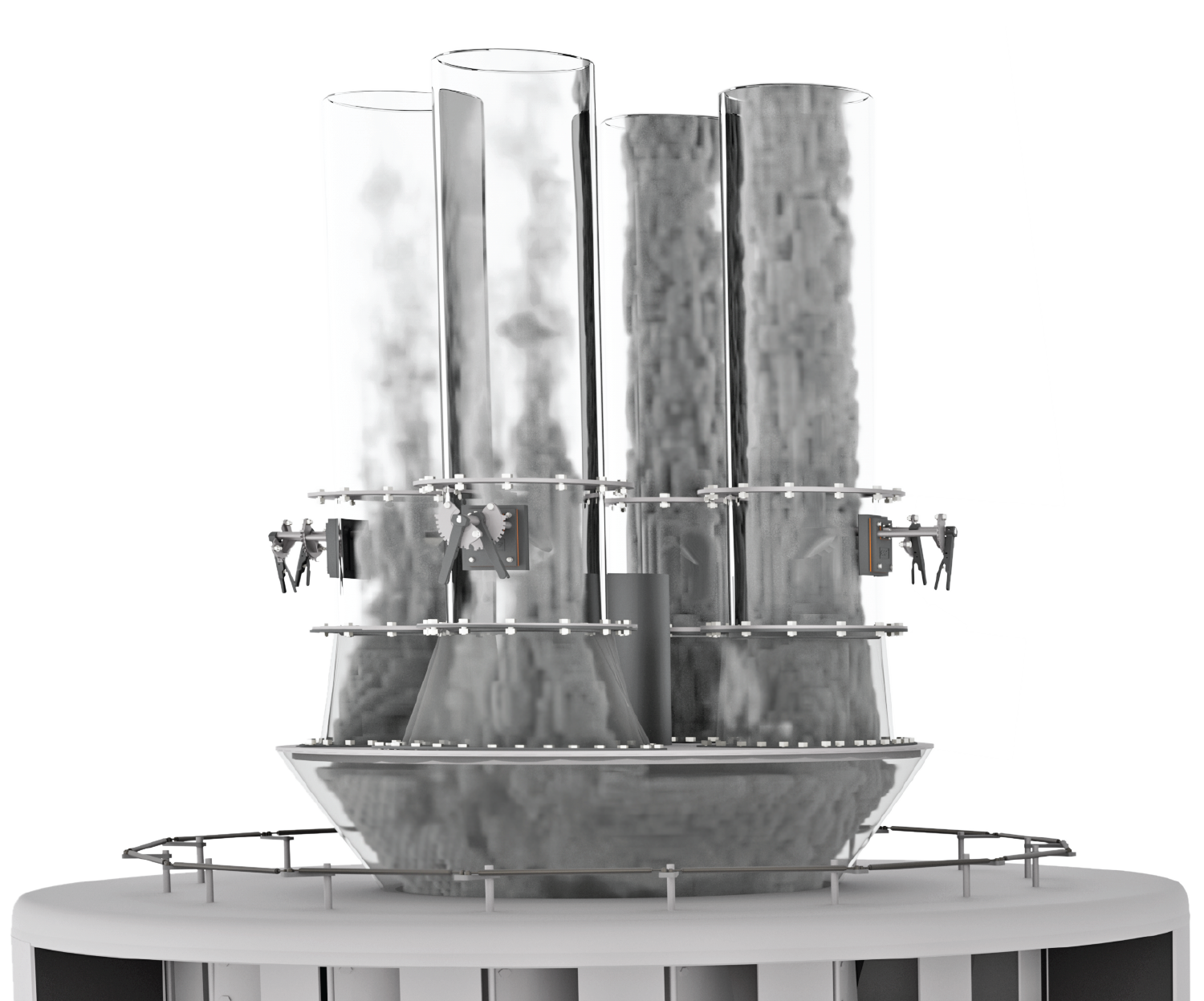

Transform your Pulverizer / Mill from this...

Coal ribboning, or roping, naturally occurs inside of the Pulverizer due to uneven coal bed depth and flow around rolls. If these ribbons of heavy fuel are allowed to continue thru the upper turret section, they will cause very unbalanced fuel distribution across the fuel pipes.

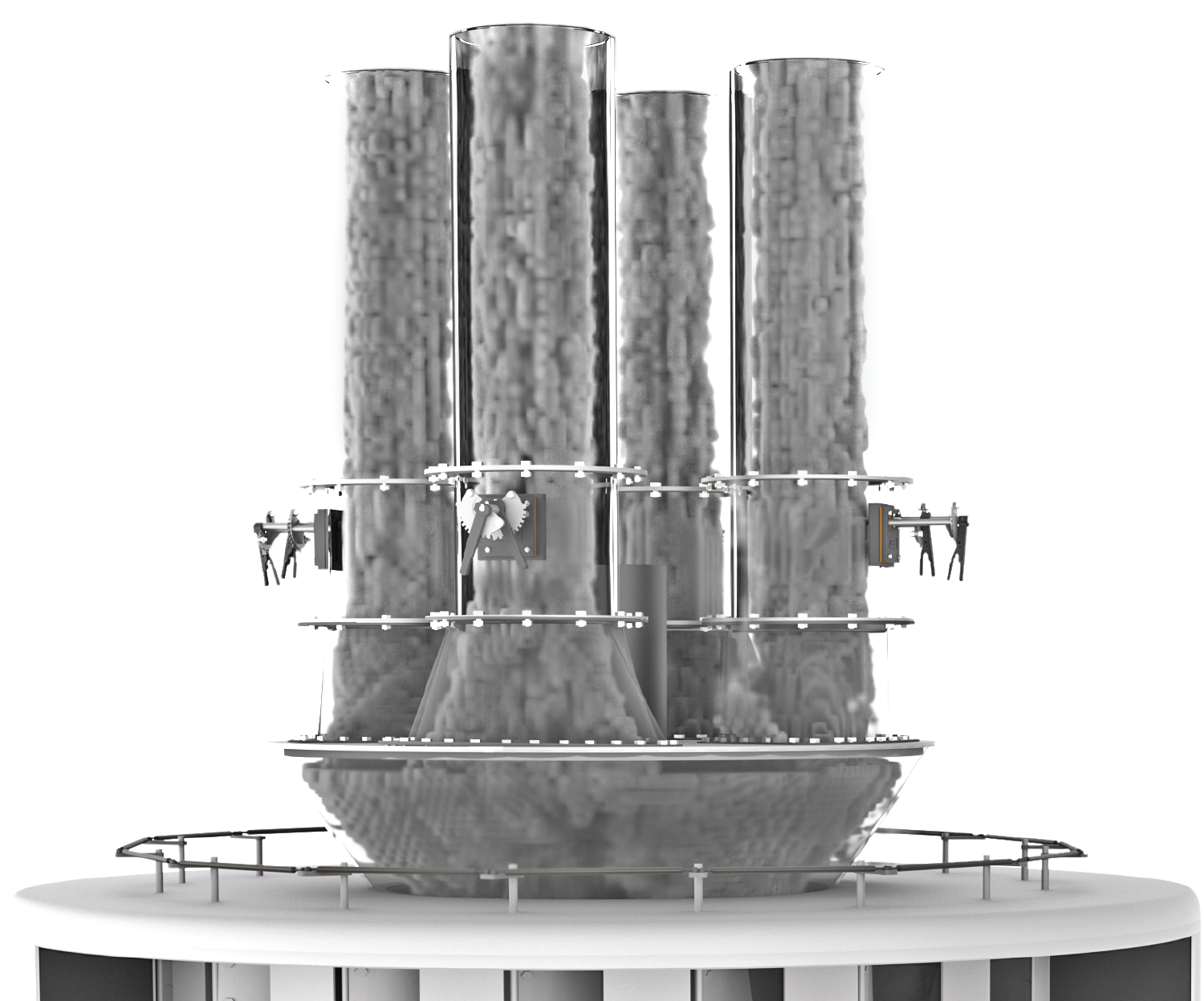

... to this with the SAS Conical Fuel Particulate Diffuser

The SAS Conical Fuel Particulate Diffuser breaks up the naturally occurring Coal ribbons and creates a homogeneous mixture of fuel and air exiting the top of the Pulverizer and entering the fuel pipes.